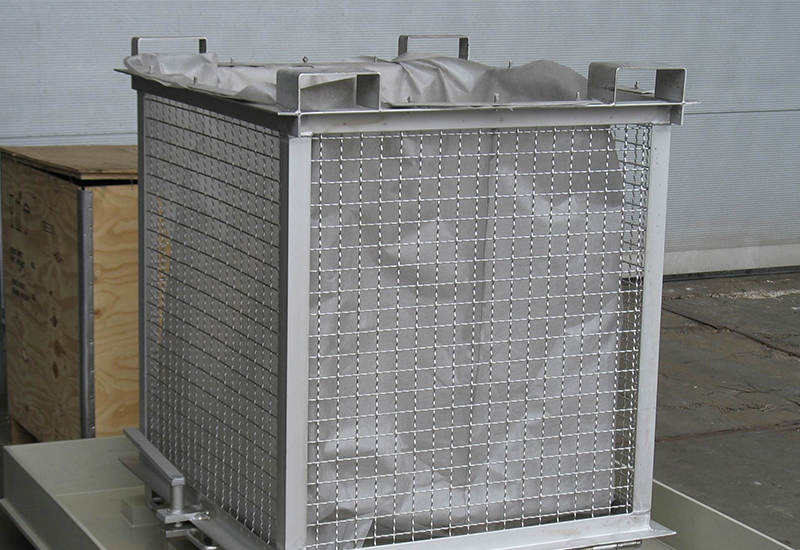

SLUDGE DEWATERING DEVICE (SCHLAMMCON)

A different way to drain

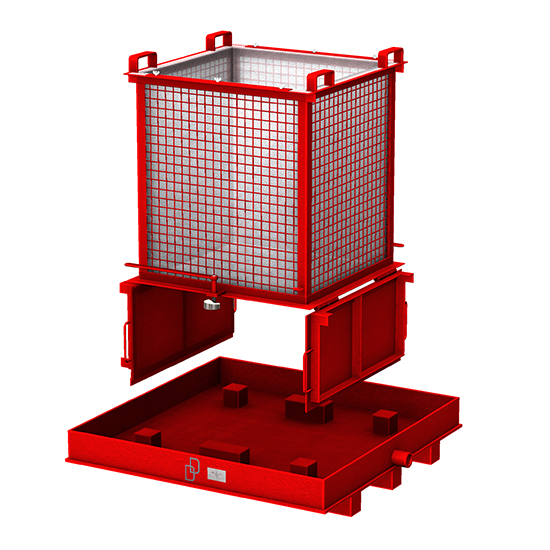

A filter box bag retains coarser particles inside the Sludge Dewatering Device. The bottom can be swung open to allow the easy disposal of the filter box bag and its contents.

The perfect way to reuse the backwash water of an automatic filter.

Technical data

Container volume

m³

Filter fineness

> µm

Manual cleaning

Yes

Filter housing

Steel, stainless steel

Advantages

- Reduction of disposal costs

- Can be combined with an automatic backwash filter or separator

- Robust design

- A drip tray allows leaked liquid to be collected for reuse

High productivity

The SCHLAMMCON is often used in combination with automatic backwash filters or separators to treat discharged backwash water.

This can eliminate the consumption of flushing water. The particles are retained in the box bags, while the purified water is collected in a drip tray and then pumped back into the system if necessary. The contents of the SCHLAMMCON can then be disposed of properly.

GET MORE

Downloads

SHAPE BETTER VALUES

CLOSER. BETTER. SIMPLER.

We will make sure that you get the filter that is perfectly tailored to your application. Our engineering office will design the filter to match your operating parameters. Our product is thus tailored specifically to your application.

Experienced partner

All DANGO & DIENENTHAL filters are handled by our specially qualified and regularly trained staff. Both our mechanical production and assembly departments have extensive expertise.

Certified testing

Our certified quality management system enables seamless monitoring and control of all production steps. This ensures early detection and troubleshooting, allowing us to offer you a high level of quality.

The team at your side

If you require staff for training or maintenance at your company, don’t hesitate to contact us. Our specially qualified employees will be happy to assist you.

Ideal production conditions

We have been producing filters in our factory in Siegen, Germany, since 1941. Our continuously improved, state-of-the-art range of machinery and modern factory buildings provide an environment that is essential for manufacturing high-quality products.

High productivity

The SCHLAMMCON is often used in combination with automatic backwash filters or separators to treat discharged backwash water.

This can eliminate the consumption of flushing water. The particles are retained in the box bags, while the purified water is collected in a drip tray and then pumped back into the system if necessary. The contents of the SCHLAMMCON can then be disposed of properly.

High productivity

The SCHLAMMCON is often used in combination with automatic backwash filters or separators to treat discharged backwash water.

This can eliminate the consumption of flushing water. The particles are retained in the box bags, while the purified water is collected in a drip tray and then pumped back into the system if necessary. The contents of the SCHLAMMCON can then be disposed of properly.