Compact automatic filter for the most difficult media

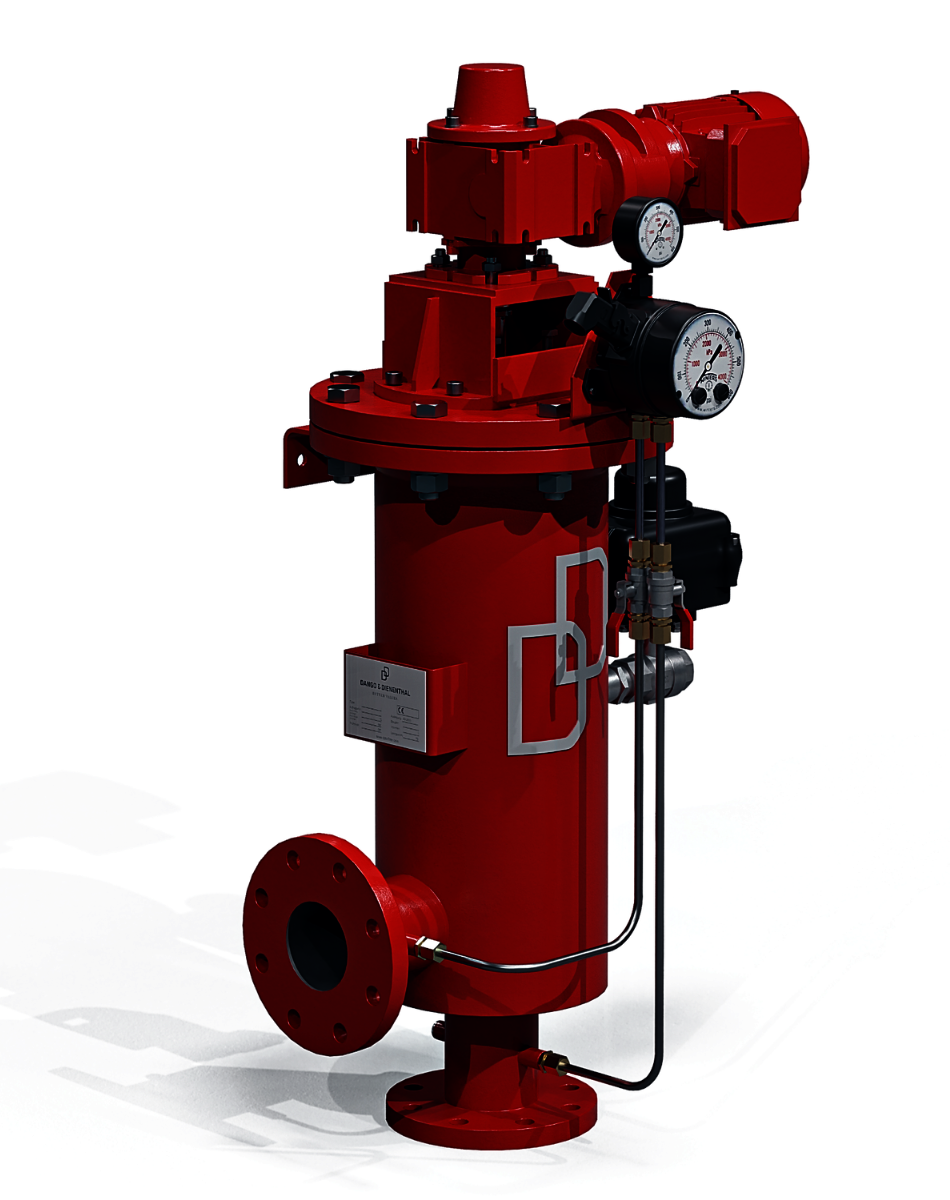

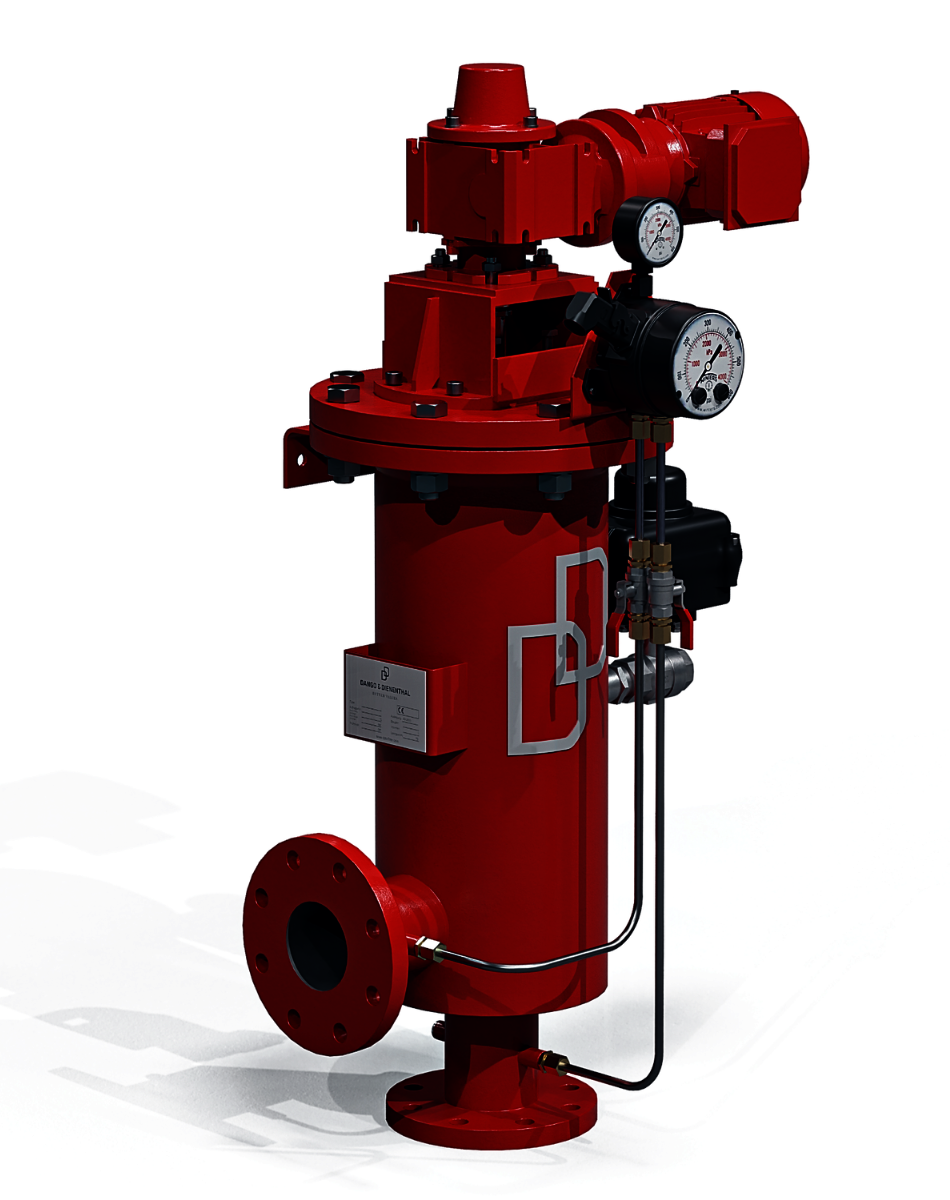

The Backwash Drum Filter S is a high-performance industrial backwash filter for reliable solid-liquid separation. It efficiently removes solids from liquids and ensures low-maintenance, continuous filtration thanks to the automatic backwash filter function. The medium flows through the rotating drum filter construction with a fine filter mesh, which reliably separates particles.

The self-cleaning water filter impresses with its fine filtration, low operating costs and durable design. Thanks to variable drum diameters, filter fineness, and materials, it offers customized solutions. The individual choice of materials enables optimum adaptation to different areas of application. Developed for low flow rates, the filter ensures precise filtration even under demanding conditions.

Request product

Download brochure now

The robust design and automatic backwash function of the industrial filter reduce maintenance costs and extend the service life of the filter element. The even loading of the entire filter surface reduces wear and spare parts costs - saving you up to 40 % in maintenance costs and ensuring efficient filtration in the long term.

Thanks to the resistant materials used, the self-cleaning water filter is suitable for high temperatures and pressures. The fine filtration from 5 μm with 100 % sealing removes even the finest particles, protects sensitive system parts and extends their service life by up to 10 years while reducing downtimes by 25-35 %.

Maximum cleaning efficiency for continuous filtration

With a cleaning speed of up to 10 m/s and 100 % cleaning of the entire filter surface, the automatic backwash filter works particularly efficiently - even with changing dirt loads. This increases your productivity by up to 20 %, avoids interruptions and ensures consistently high operational reliability.

Versatile applications in various industries

Ideal for water treatment, the food industry, the chemical industry, and wastewater treatment. This industrial backwash filter ensures reliable solid-liquid separation and is optimized for demanding applications. To assist with cleaning the filter element, the RTF-S can also be fitted with a scraper on the rinsing window.

Comprehensive protection for systems and media

Our filter systems reliably protect plate heat exchangers, spray nozzles, piping systems, mechanical seals, pumps, and microfiltration systems. They guarantee maximum purity for various media, such as cooling water, river water, process water, oils, emulsions, and drinking water. Even in mussel-infested waters, they ensure efficient filtration and long-term protection for sensitive systems.

WHY A BACKWASH FUNCTION?

The backwash function ensures continuous filtration by removing accumulated solids from the filter element. It prevents clogging, reduces maintenance efforts, and ensures consistently high filtration performance without interrupting operation.

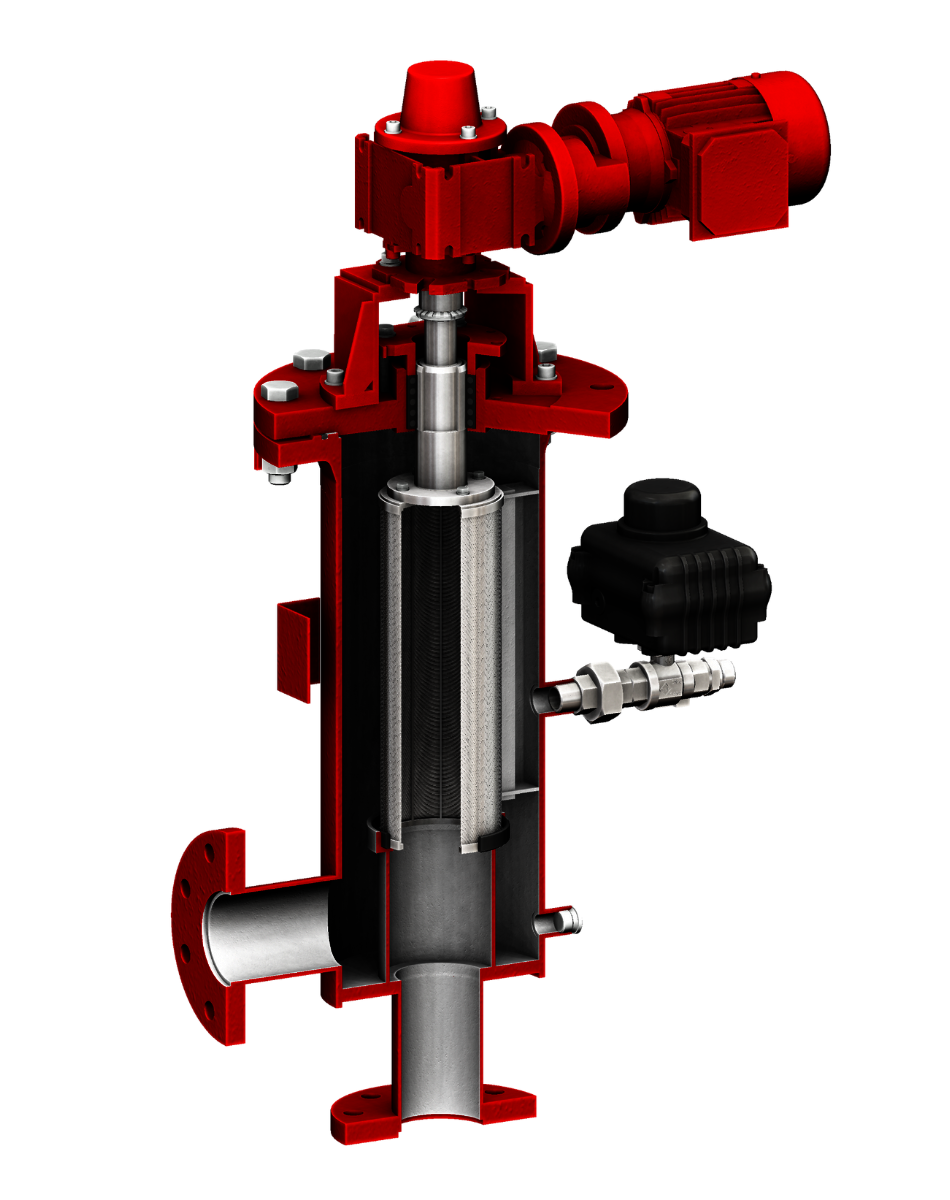

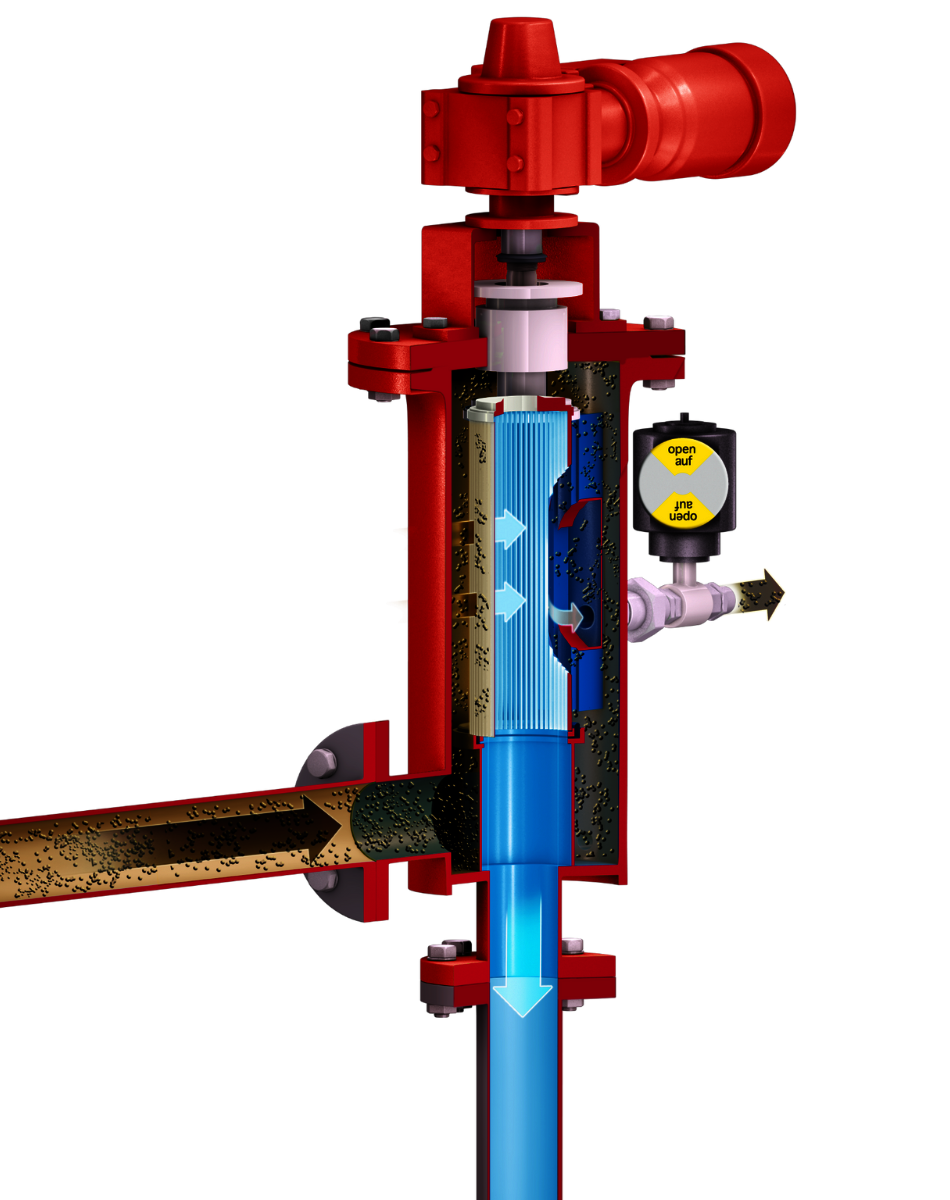

HOW DOES THE BACKWASH FUNCTION WORK?

A differential pressure measurement detects the degree of contamination of the filter element and activates backwashing when a defined value is reached. The motor-driven backwash valve opens, generating atmospheric pressure. The clean water pressure flushes the solids out of the filter mesh against the direction of filtration. The rotation of the filter element ensures complete cleaning before the backwash valve closes again automatically after 15-20 seconds. During this time, filtration continues without interruption. The optimized backwash function significantly reduces flushing water losses, keeping water consumption to a minimum.

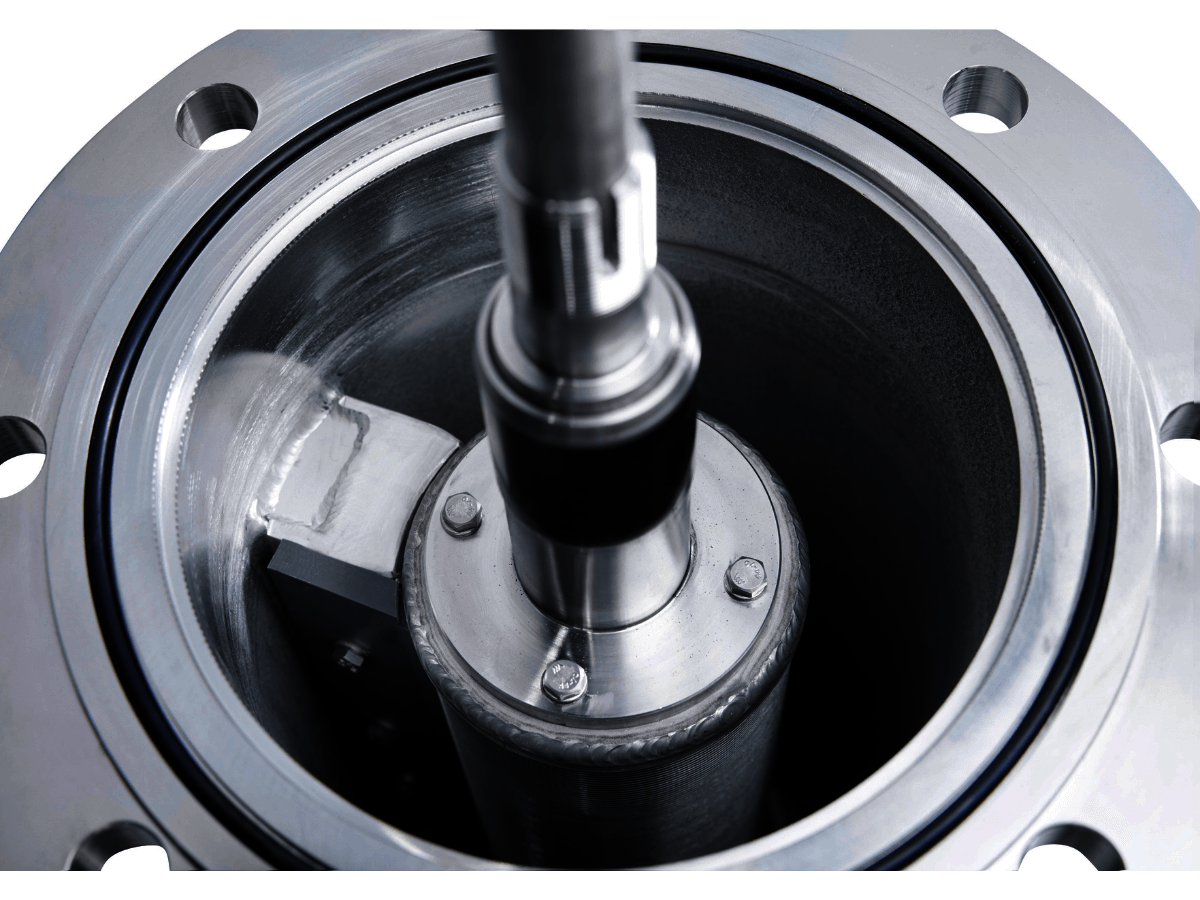

Filter element

The filter element is made of durable stainless steel to maximize the service life. The filter cartridge contains a wound wedge-wire screen cylinder with shaft support. The wedge-wire screen made of welded triangular rods offers high stability and is available in various stainless steel grades with a filter fineness starting from 5 µm. 100 % cleaning of the entire filter surface ensures less pump energy due to constant differential pressures. Depending on the operating conditions and pump performance, this saves you 10-30 % of energy costs, reduces your operating costs and also makes your contribution to sustainability.

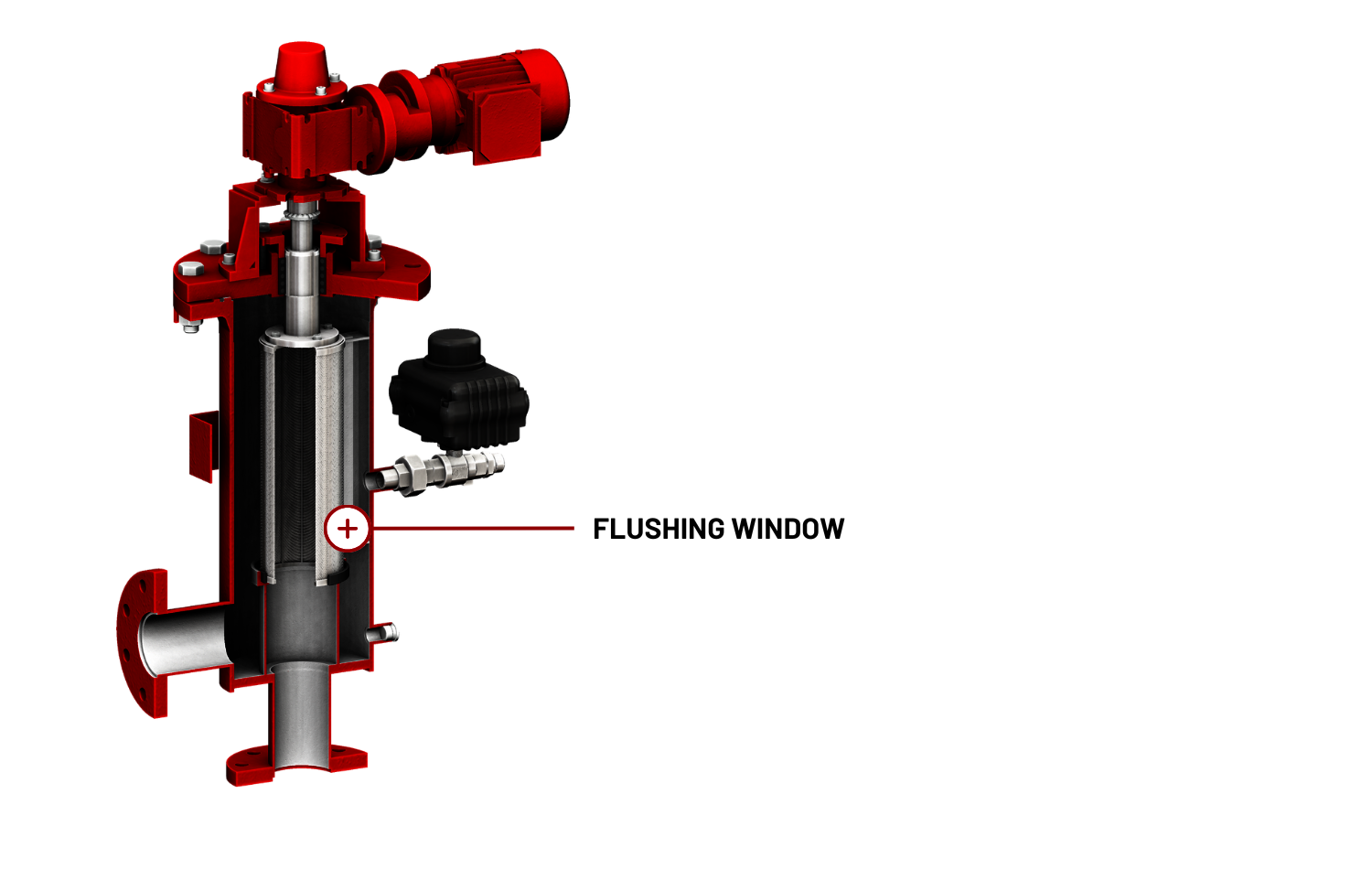

Flushing window

During backwashing, the filter element rotates along the flushing window, effectively removing retained particles. This ensures efficient and uninterrupted filtration.

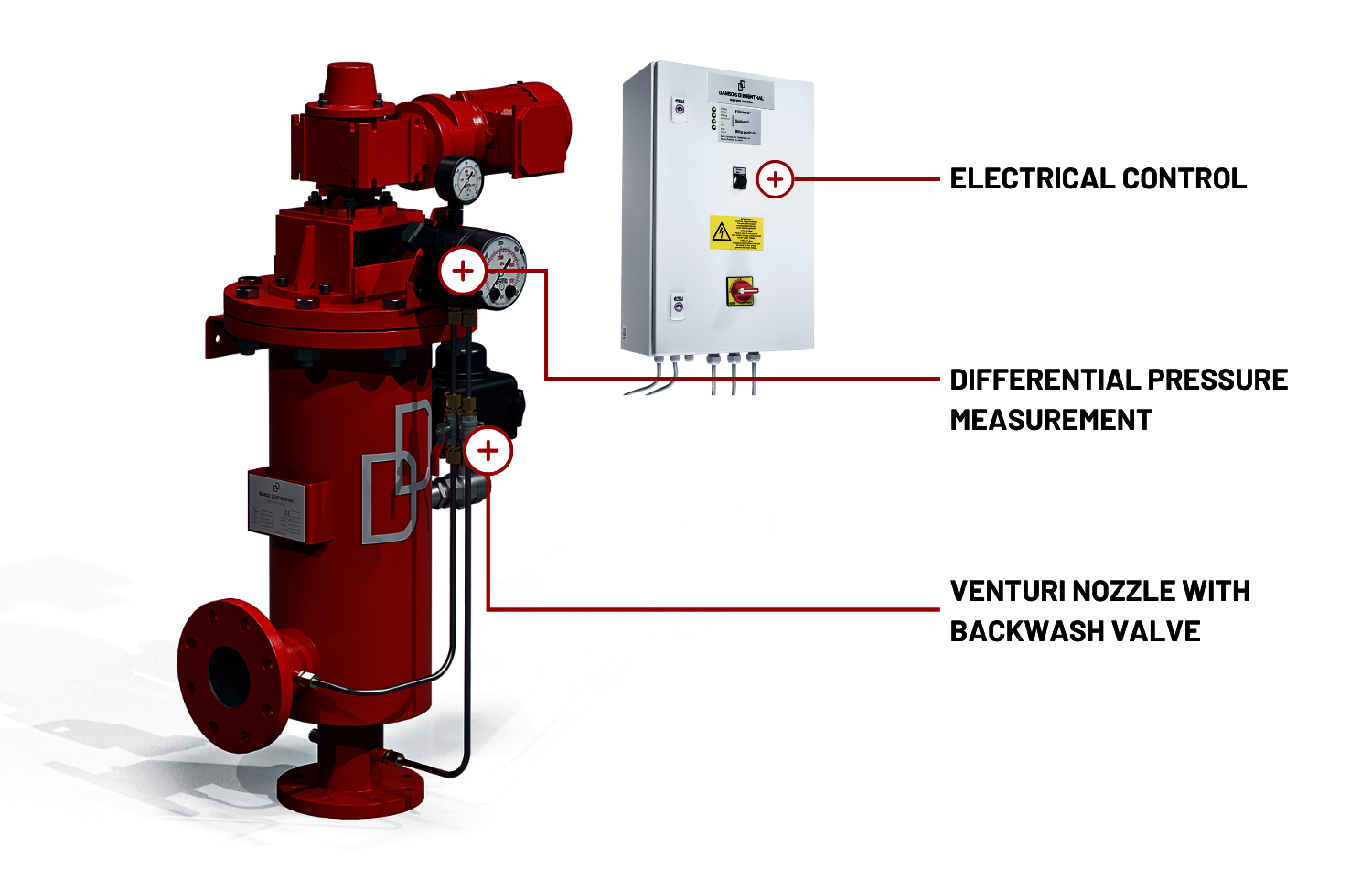

Electrical control system

The backwash process is initiated automatically depending on the time or differential pressure control. The control system enables fully automatic operation with signal exchange to the process control system (PCS), including operating status, faults, and external backwash triggering.

![[Translate to English:] elektrische steuerung des JET Filters](/fileadmin/_processed_/b/e/csm_elektrische-steuerung_024cea25a7.jpg)

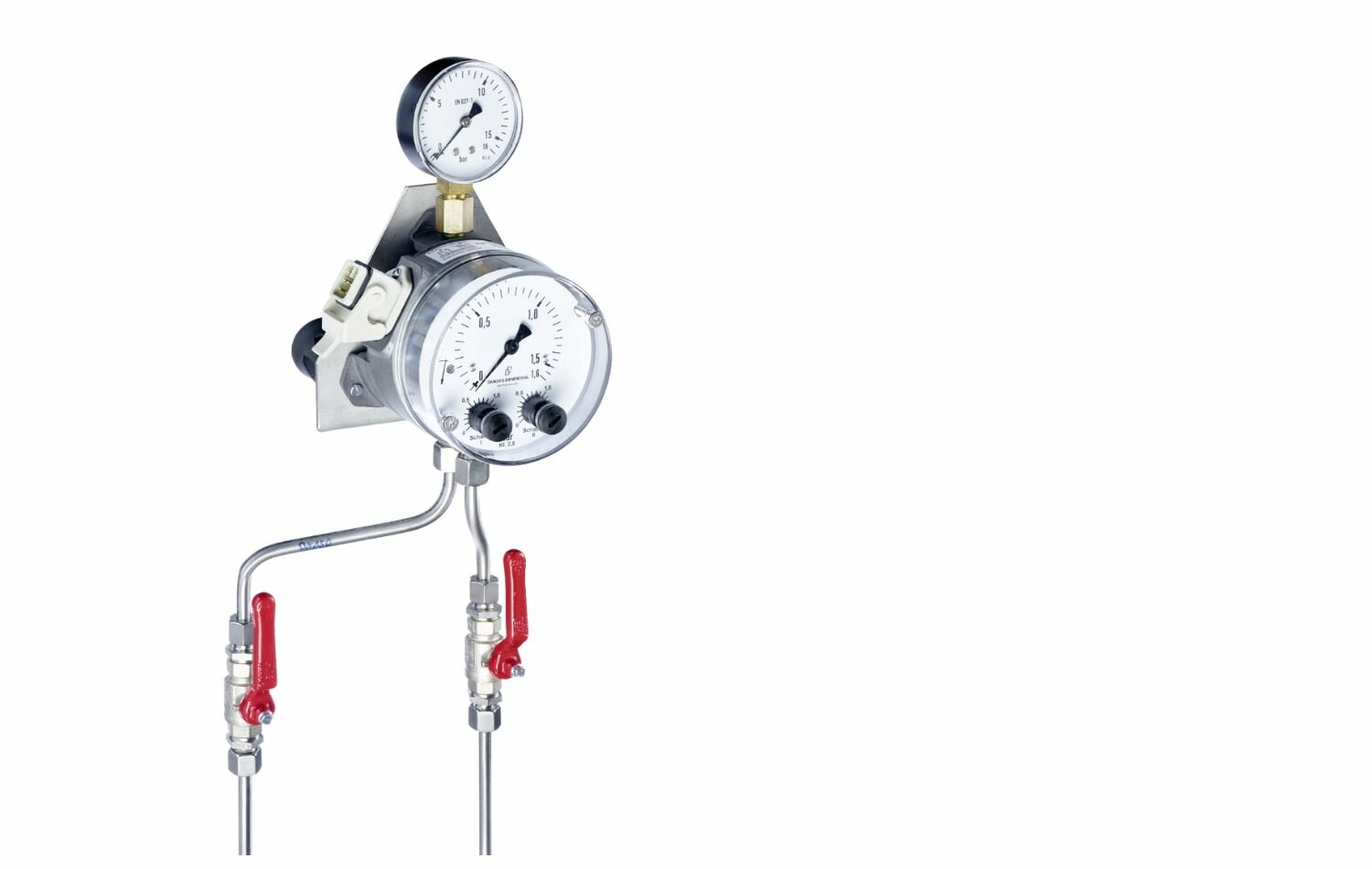

Differential pressure measurement

An optical display shows the operating and differential pressure. Two adjustable switching contacts enable automatic flushing control and alarm messages to ensure reliable filtration performance.

Venturi nozzle with backwash valve

The Venturi nozzle adapts to the operating conditions and regulates the amount of flushing water to prevent pressure fluctuations in the pipe network. This saves you up to 70 % of your rinsing water consumption, halves your disposal costs and protects the ecosystem at the point of use. The backwash valve is equipped with an electric or pneumatic actuator as standard and ensures precise control of the flushing process.

CONTACT

Are you interested in our product?

Then contact us via contact form, post@dds-filter.com or +49 271 401 4123.

We look forward to your inquiry!