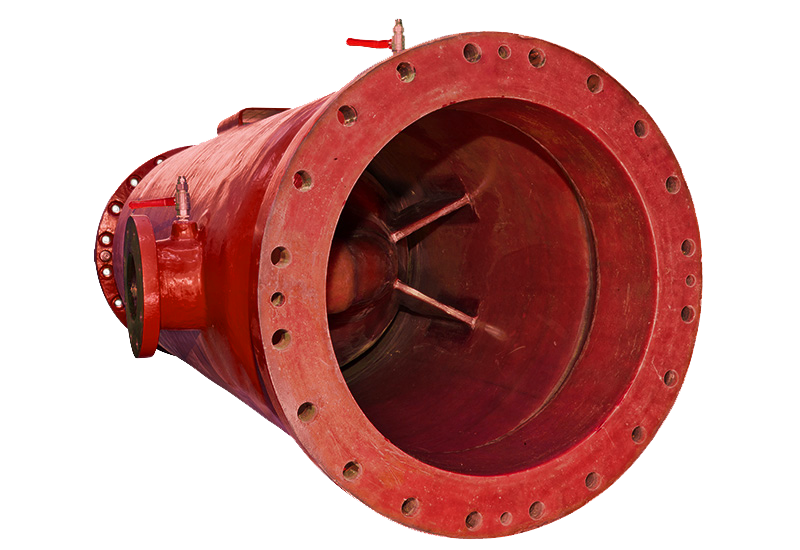

JET FILTER (JET)

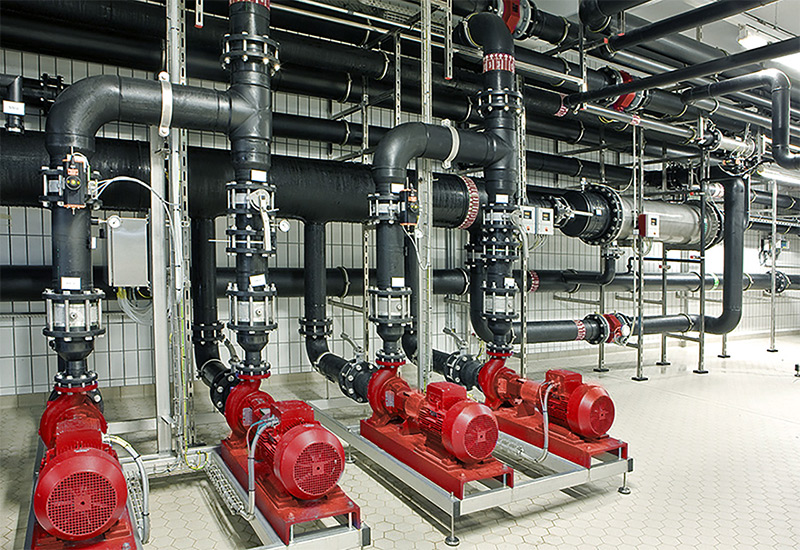

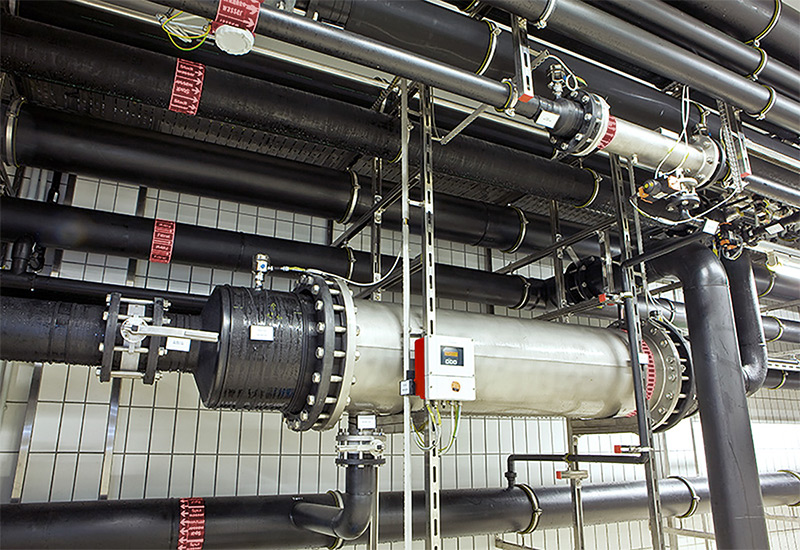

Filtration in any position

The JET filter is an inline filter without any moving internal parts. Its patented design enables very high flow rates, a high diversity of materials and flexible installation in pipelines.

The JET filter is ideally suited for all installation situations, and with minimal wear.

Technical data

Flow rate

max. m³/h

Filter fineness

> µm

Operating pressure

1.5 to bar

Flanges

DN 50 to

Automatic cleaning

Yes

Filter housing

Steel, stainless steel, GRP, plastic

Advantages

- High cleaning speed (up to 10 m/s)

- Any installation position (horizontal/vertical)

- Easy installation (inline design)

- Low wear (no moving parts in the filter)

- Low flushing water losses

- No increase in differential pressure during filter operation

- Diversity of materials

- Completely wired and tested unit

- Special design solutions for special customer requirements

High productivity

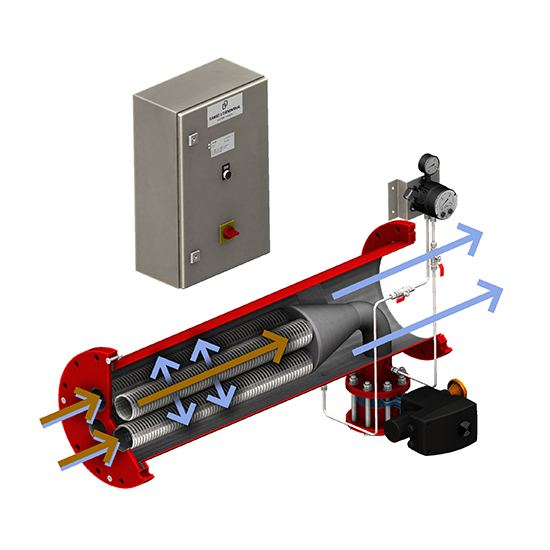

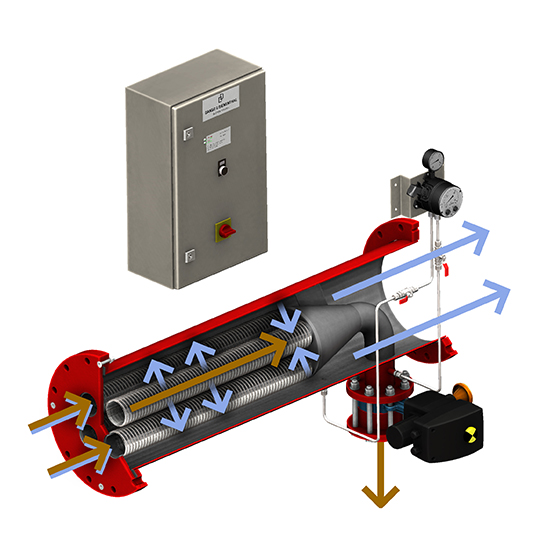

The raw water flows through the openings in the clamping plate, entering the filter elements located behind them. The reductions in cross-section bring about a proportional increase in the axial flow velocity in the filter elements of 5-7 m/s. There is a conical dirt collection container located at the end of the filter elements, into which all the filter elements are brought together.

The raw water is filtered according to Bernoulli's law in the last third section of the filter elements. The raw water flows through the filter elements from the inside to the outside. The clean water then flows around the dirt collection container and exits the JET Filter on the clean water side.

The axial flow velocity in the filter elements of 5-7 m/s guides the dirt particles into the conical dirt collection container. The filter backwash process is initiated by the differential pressure (the pressure difference between the raw and clean water side). An adjustable time relay in the electrical control system additionally enables the filter backwash process.

Backwashing

At the start of filter cleaning, the motor-driven backwash valve opens. A small amount of the raw water then flows through the backwash opening. This flushes the dirt particles in the dirt collection container out of the filter. During backwashing, the axial flow velocity in the filter elements increases to up to 10 m/s.

This high axial velocity additionally cleans the filter elements. Furthermore, a vacuum is generated in the filter elements, which guarantees that backwashing proceeds from the outside to the inside with clean water. The backwash process is complete after 10-20 seconds and the backwash valve is closed automatically. Filtration is not interrupted during backwashing.

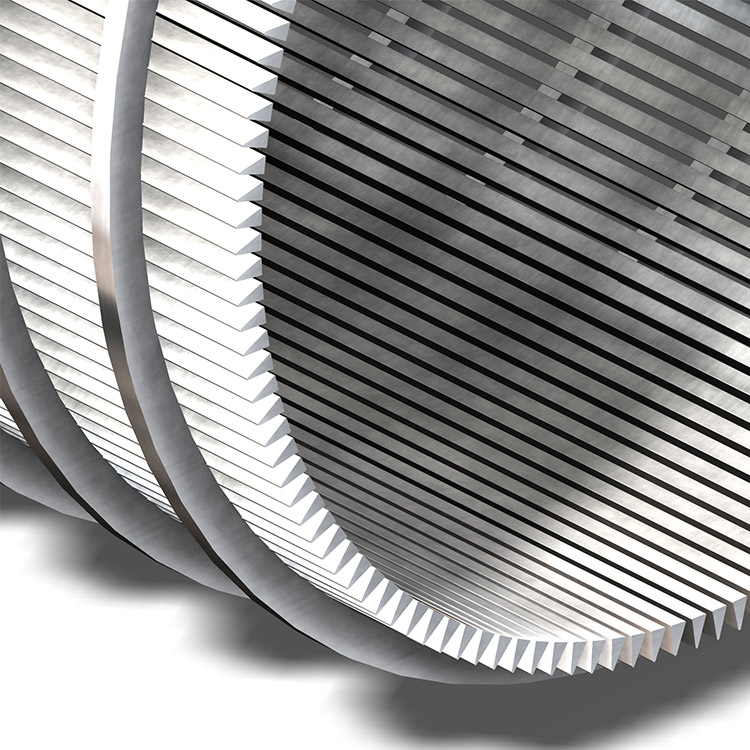

Stainless-steel wedge-wire screen cylinder with axial gaps for optimal filter element cleaning.

EXPECT MORE

HOW TO GET RID OF MUSSELS

Mussels and mussel larvae are fast becoming a major threat to industry. Once mussels or their larvae are in your system, they can multiply unhindered and incapacitate entire pipeline networks. The unique MUSSEL STOP system from DANGO & DIENENTHAL offers reliable protection for your plant components against unwanted mussel infestation, thereby minimizing breakdowns and maintenance costs.

GET MORE

Downloads

SHAPE BETTER VALUES

CLOSER. BETTER. SIMPLER.

We will make sure that you get the filter that is perfectly tailored to your application. Our engineering office will design the filter to match your operating parameters. Our product is thus tailored specifically to your application.

Experienced partner

All DANGO & DIENENTHAL filters are handled by our specially qualified and regularly trained staff. Both our mechanical production and assembly departments have extensive expertise.

Certified testing

Our certified quality management system enables seamless monitoring and control of all production steps. This ensures early detection and troubleshooting, allowing us to offer you a high level of quality.

The team at your side

If you require staff for training or maintenance at your company, don’t hesitate to contact us. Our specially qualified employees will be happy to assist you.

Ideal production conditions

We have been producing filters in our factory in Siegen, Germany, since 1941. Our continuously improved, state-of-the-art range of machinery and modern factory buildings provide an environment that is essential for manufacturing high-quality products.