PRODUCTS TO MAKE MORE

Steel industry

The steel industry is one of the world's most important industrial sectors. A high standard of quality is expected for a wide range of applications, from aluminum foil to steel beams. Our filter systems offer your plants a high level of productivity with continuous process reliability.

Application

In the steel industry, large quantities of water are required for cooling as well as in a number of different manufacturing processes (e.g. continuous casting plants, rolling mills, etc.). Most of the water used for this purpose is river, well, or sea water. Depending on the degree of contamination, water from these sources can have considerably adverse effects on the plant components. These usually include heat exchangers or spray nozzles that become clogged over time, but contaminated water can also play havoc with seals, pumps or entire pipe systems. The various filter systems from DANGO & DIENENTHAL can provide the best possible protection for your plant components, prevent production downtimes and considerably lower maintenance costs.

The result

- Consistent product quality due to failure-free spray nozzles

- Reduced maintenance intervals for heat exchangers

- Reliable separation of sinter and scale

- No mussel infestation in the pipeline

Areas of application

- Protection of heat exchangers

- Protection of spray nozzles

- Filtration of make-up water

- Scale separation

- Protection of booster pumps

- As a substitute for sand filters

- Protection against mussels and mussel larvae

PRODUCTS

MADE FOR MORE

![[Translate to English:] [Translate to English:] Filterautomat DDF für Fest-Flüssig-Trennung](/fileadmin/_processed_/7/f/csm_filterautomat-ddf-wasseraufbereitung_8f6faa2b29.png)

Filterautomat

Extremely robust automatic filter

The Filterautomat boasts an extremely robust design and excellent backwash performance. The rotating filter drum distributes any solids uniformly over the entire filter surface and filters it out effectively.

![[Translate to English:] [Translate to English:] Rückspül-Trommelfilter für Fest-Flüssig-Trennung](/fileadmin/_processed_/5/b/csm_rueckspuel-trommelfilter-hp-fest-fluessig-trennung-00_eb35d39b57.png)

Backwash Drum Filter

Automatic filters for the most difficult media

The Backwash Drum Filter is based on the filtration and backwash principle of the Filterautomat. A more customized selection of materials is possible for the most difficult media.

![[Translate to English:] [Translate to English:] Rückspül-Trommelfilter S für Fest-Flüssig-Trennung](/fileadmin/_processed_/a/9/csm_rueckspuel-trommelfilter-s-fest-fluessig-trennung_8376fe6c3c.png)

Backwash Drum Filter S

Compact automatic filter for the most difficult media

This filter impresses with excellent backwash performance and a compact design. A customized selection of materials is possible for the most difficult media.

![[Translate to English:] [Translate to English:] JET Filter für Fest-Flüssig-Trennung](/fileadmin/_processed_/0/3/csm_jet-filter-fest-fluessig-trennung_3117320359.png)

JET Filter

Automatic filter with no moving parts

The JET filter is an inline filter without any moving internal parts. Its patented design enables very high flow rates, a high diversity of materials and flexible installation in pipelines.

![[Translate to English:] [Translate to English:] JET Filter S für Fest-Flüssig-Trennung](/fileadmin/_processed_/f/0/csm_jet-filter-s-fest-fluessig-trennung_ff71cc46b5.png)

JET Filter S

Compact automatic filter with no moving parts

Due to its electronic controller, the JET Filter S is immediately ready for use as a complete module. The filter element can be exchanged without removing the filter.

![[Translate to English:] [Translate to English:] Plattenfilter für Fest-Flüssig-Trennung](/fileadmin/_processed_/9/0/csm_plattenfilter-fest-fluessig-trennung_7d58693d8e.png)

Plate Filter

Massive inline filter for coarse filtration

The plate filter is a solid inline filter with an inclined filter plate. Both manual and automatic backwashing is possible with this model.

![[Translate to English:] Single filter for solid liquid separation](/fileadmin/_processed_/8/d/csm_einfachfilter-fest-fluessig-trennung_6c9726f3f3.png)

Single Filter

Manual filter – pure and simple

Compact solution for efficient solid-liquid separation - DD single filters are versatile, robustly designed and enable quick maintenance.

![[Translate to English:] duplex filter for solid liquid separation](/fileadmin/_processed_/c/b/csm_doppelfilter-fest-fluessig-trennung_b59ba4bb04.png)

Duplex Filter

Continuous filtration with manual switching

Reliable filtration with integrated switchover function - DD Duplex filters ensure continuous operation, minimize downtimes and are ideal for demanding industrial processes with high availability.

Bag Filter

Manual filtration down to 1 Micrometer

The filter element of this manual filter can be made of different materials, such as nylon or needle felt.

Multi-Bag Filter

Bag filter for higher flow rates

The Multi-Bag Filter includes multiple filter bags integrated into a single filter housing. This allows higher flow rates and longer operating times.

![[Translate to English:] [Translate to English:] Schlammentwässerungsgerät zu Filterlösungen](/fileadmin/_processed_/a/4/csm_SCHLAMMCON-fest-fluessig-trennung_e1d47d6ab8.png)

SLUDGE DEWATERING DEVICE

For backwash water treatment

A filter box bag retains coarser particles inside the Sludge Dewatering Device. The bottom can be swung open to allow the easy disposal of the filter box bag and its contents.

![[Translate to English:] separators for solid liquid separation](/fileadmin/_processed_/0/0/csm_separatoren-fest-fluessig-trennung_1a12cd3638.png)

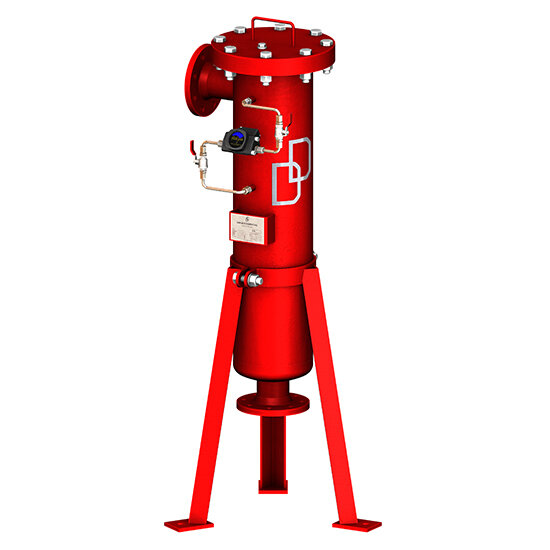

Separator

Filter with centrifugal separation

The separators reduce the load on downstream filter systems, improve filtration performance and are ideal for applications with a high solids input and a high degree of contamination.

Project request

Are you planning a new project? Then let us support you. If you give us information about your requirements and the boundary conditions, our experts will be happy to contact you.

Ask for more