Precise solid-liquid separation for industrial applications

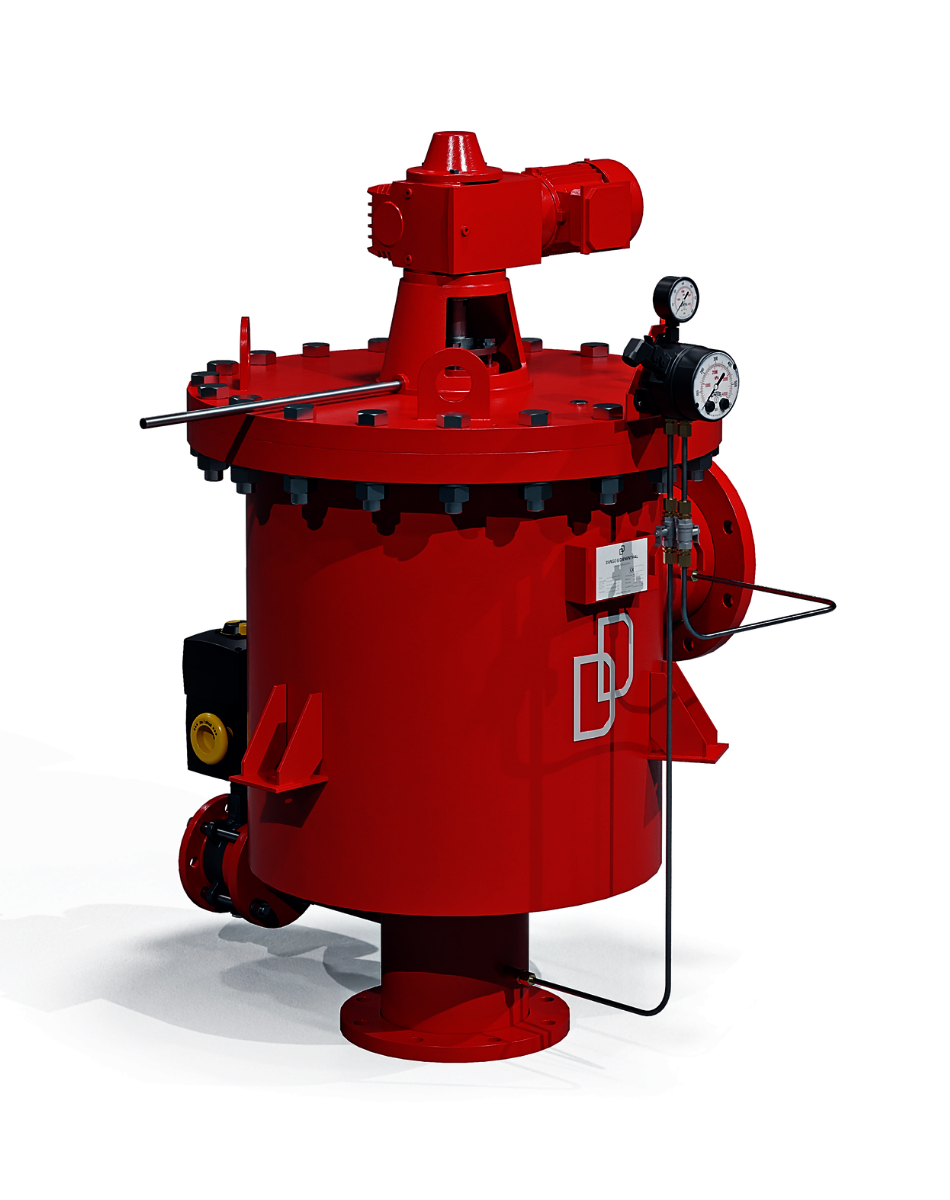

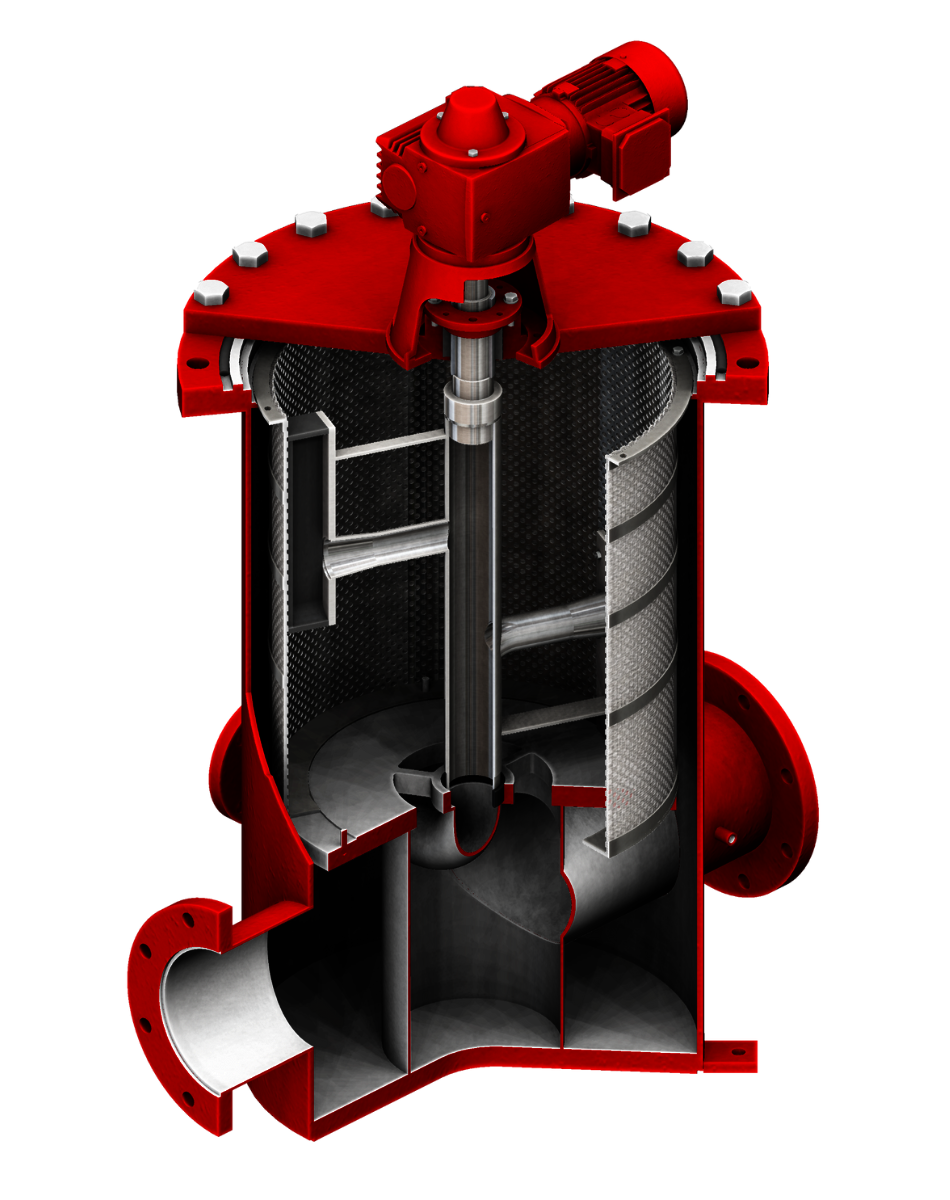

The HP Backwash Drum Filter HP is a high-performance water filter that removes large quantities of solids from liquids. The liquid flows through the fine-mesh drum filter design, which reliably retains particles. Its robust design and individual choice of materials and sizes make it ideal for demanding media.

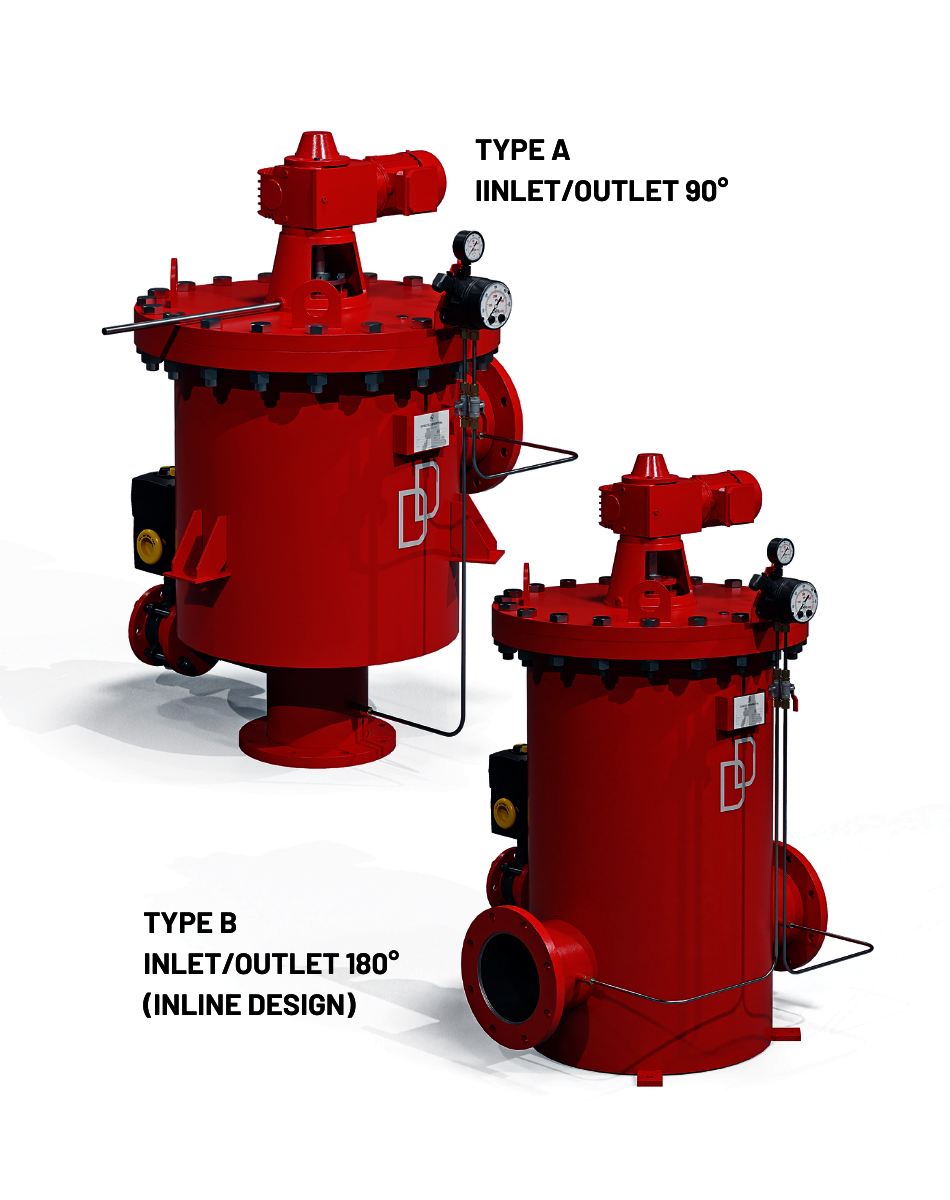

Various flange options facilitate integration into existing pipe systems and make the self-cleaning water filter flexible for use in industrial filter systems. Thanks to its high filtration performance, maintenance-friendly design, and long service life, this automatic backwash drum filter offers a cost-effective and reliable solution for industrial solid-liquid separation.

Request product

Download brochure now

The industrial filter provides precise solid-liquid separation at cleaning speeds of up to 10 m/s and 100% cleaning of the entire filter surface. At the same time, fine filtration down to 5 μm protects sensitive system parts from premature wear.

The result: up to 20 % more productivity, up to 35 % less downtime and a significantly longer service life for your system - even with highly variable dirt loads.

Thanks to the balanced loading of the entire filter surface, the self-cleaning water filter works particularly efficiently and with low wear. The automatic backwash function ensures reliable filtration with minimal maintenance.

This extends the service life of the filter element, reduces replacement part costs and saves up to 40 % of maintenance costs for permanently constant filtration performance with optimized operating processes.

High cleaning efficiency

Thanks to 100% cleaning of the entire filter surface and minimal flushing water losses, the filtration performance remains permanently high. The efficient backwash system of the automatic backwash drum filter ensures continuous filtration without interrupting operation.

Robust design for durable and reliable operation

The drum filter combines robust materials with a space-saving inline design. It can be installed flexibly, requires hardly any floor space and fits into existing systems without pipe conversions. This saves you up to 40 % installation costs and ensures efficient solid-liquid separation with a high flow rate.

Reliable protection for systems and liquid media

Our filter systems protect plate heat exchangers, spray nozzles, piping systems, mechanical seals, pumps, and microfiltration systems from contamination. They guarantee first-class filtration for cooling water, river water, process water, oils, emulsions, and drinking water. Even in mussel-infested waters, they offer reliable protection and long-term operational reliability for sensitive systems.

WHY A BACKWASH FUNCTION?

The backwash filter function removes accumulated solids from the filter element, ensuring uninterrupted filtration performance. It prevents clogging, reduces maintenance, and ensures efficient, continuous filtration with minimal water loss. In industrial filter systems in particular, this function ensures low operating costs and a long service life.

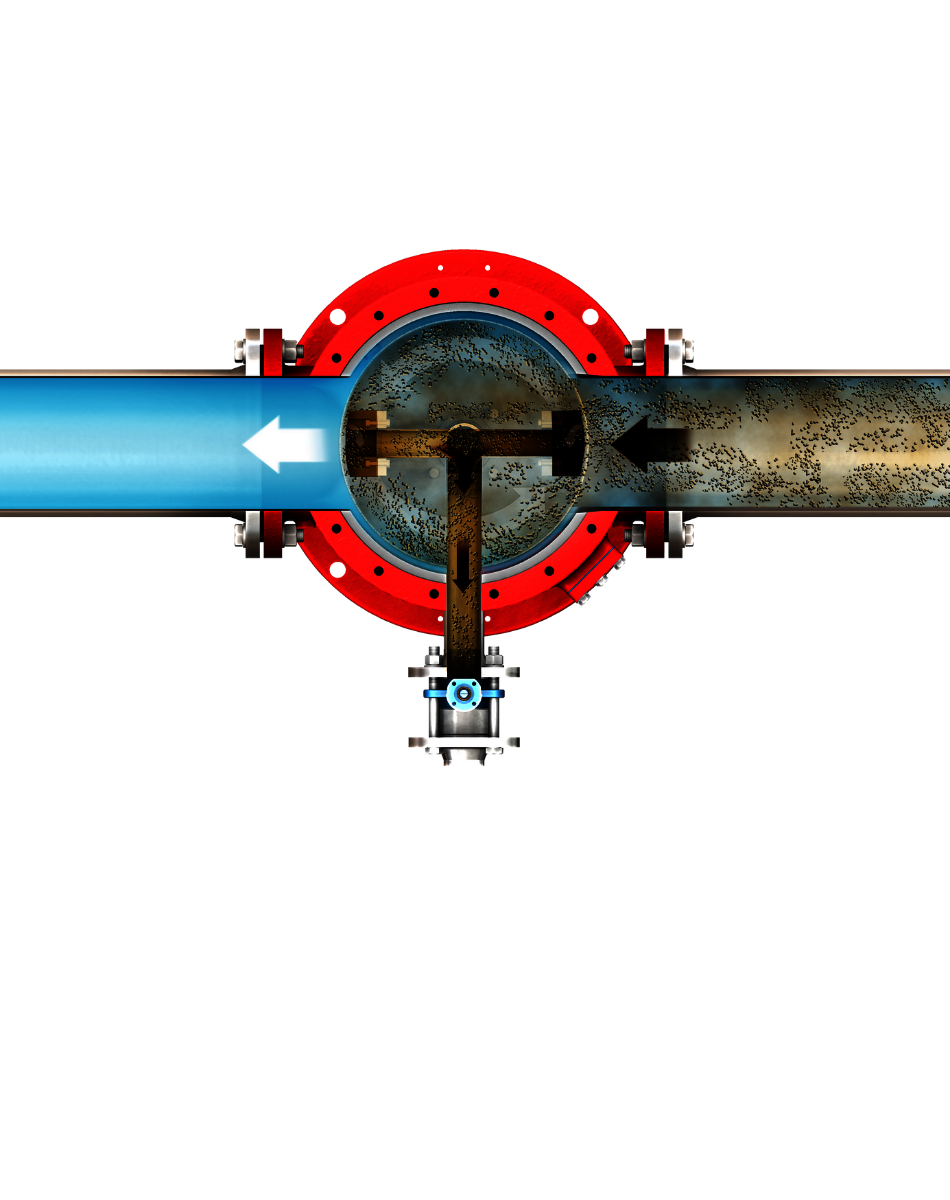

HOW DOES THE BACKWASH FUNCTION WORK?

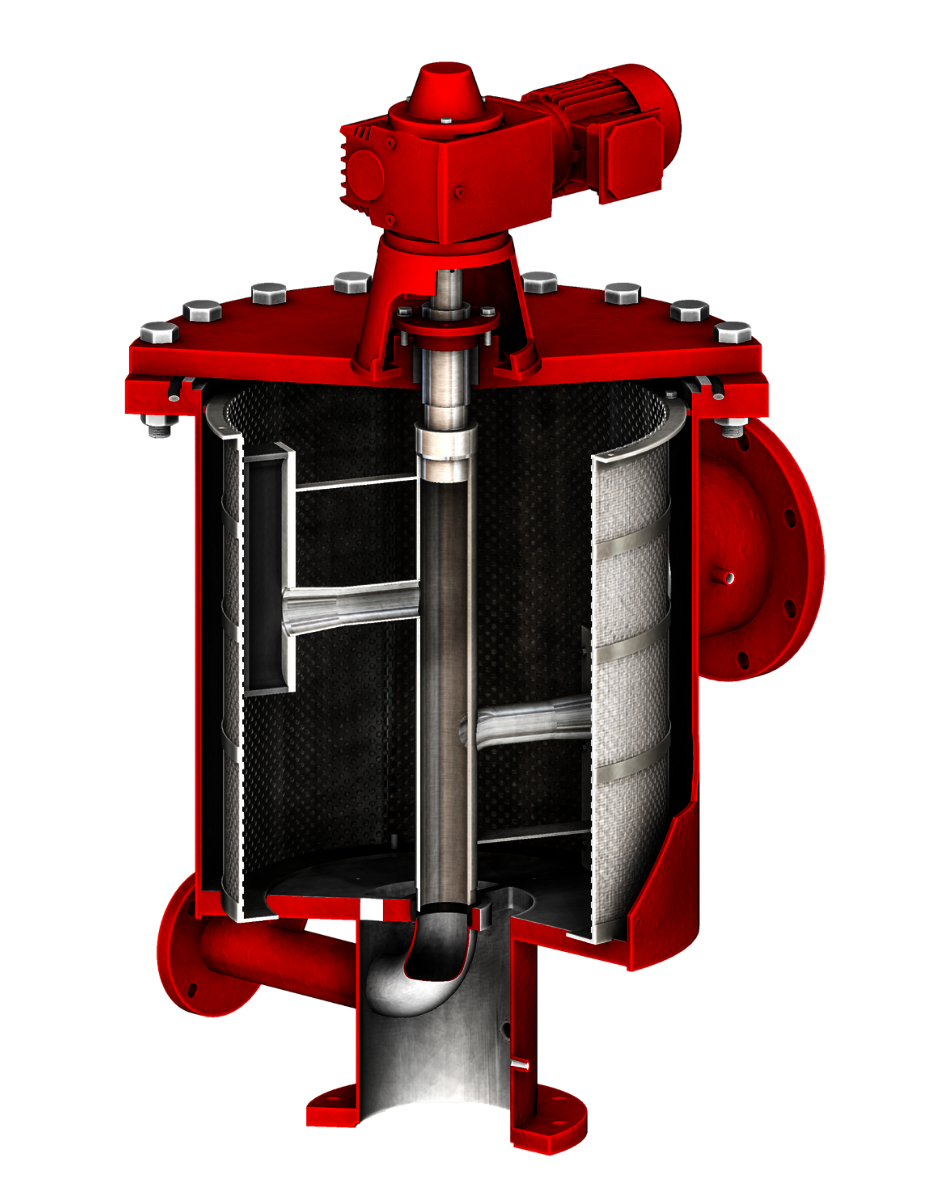

The backwashing of the drum filter starts automatically as soon as the differential pressure measurement detects contamination. A motor-driven backwash valve opens, generating atmospheric pressure. The excess pressure on the clean water side pushes the solids out of the filter against the direction of filtration. The filter basket of the self-cleaning water filter is completely cleaned in 15-20 seconds through the rotation of the flushing shoes. This automatic backwash filter function enables reliable solid-liquid separation without interrupting the filtration process.

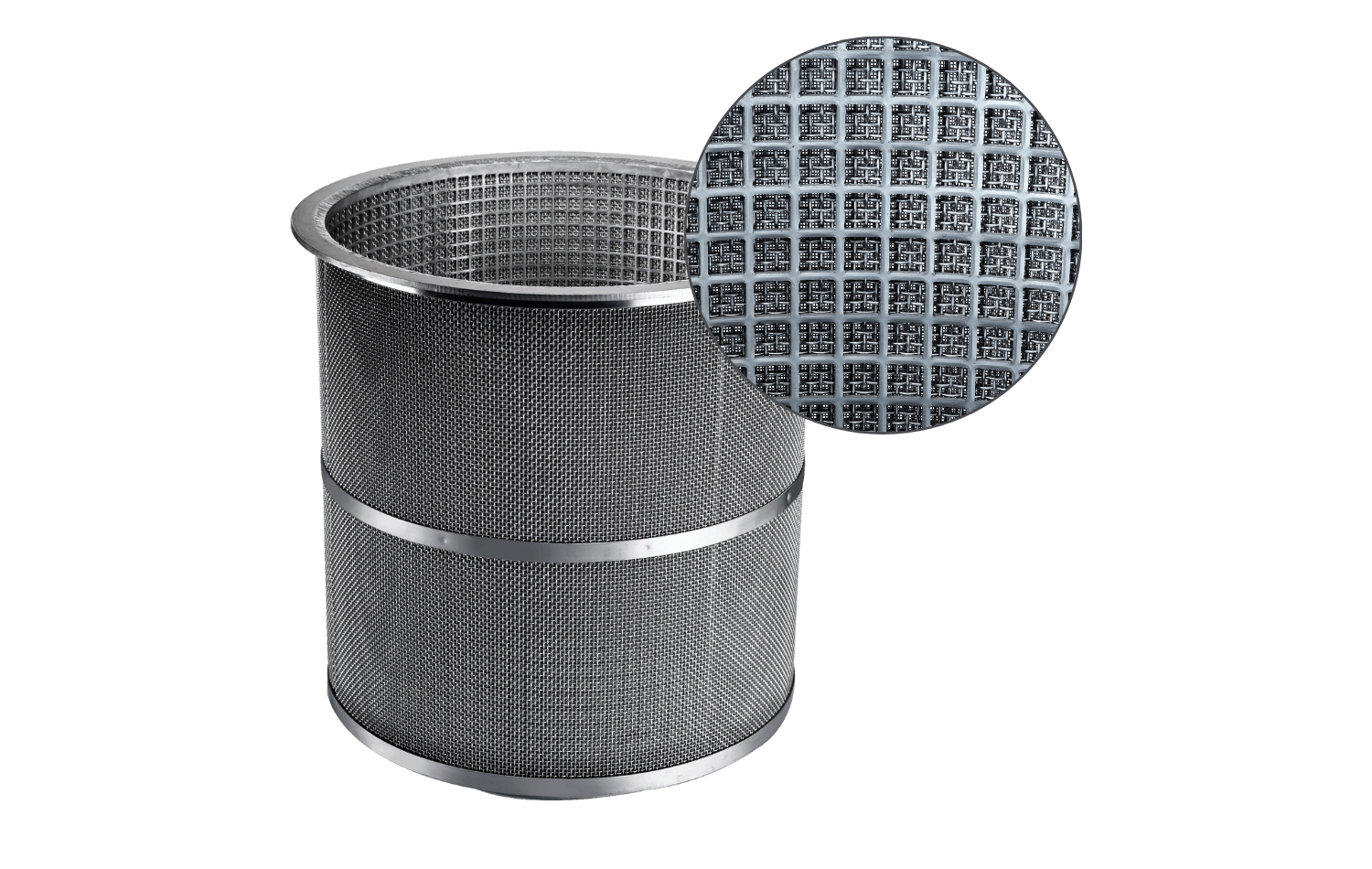

Filter element

The wire mesh consists of a robust sandwich construction with two supporting meshes that enable a high net filter area utilization. It is available in various stainless steel grades and offers filter finenesses from 5 μm for precise filtration. Differential pressures remain stable thanks to 100 % cleaning of the entire filter surface. Depending on the operating conditions, this reduces energy costs by up to 30 % and increases the sustainability of your system.

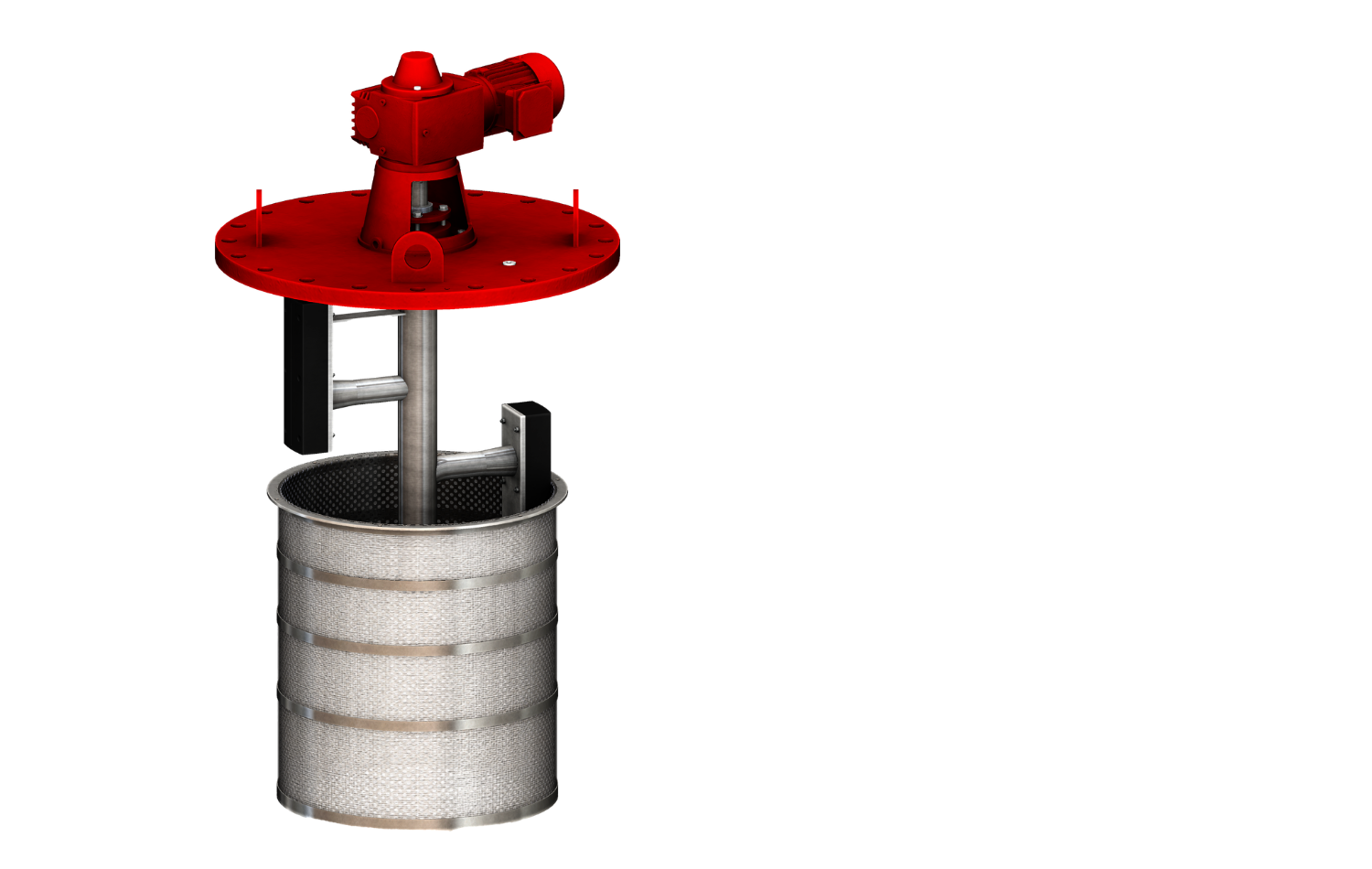

Flushing shoes

The two opposing flushing shoes are mounted on the flushing arm inside the filter. During the flushing process, this device rotates, cleaning the filter element. The flushing shoes are corrosion-resistant and easy to replace.

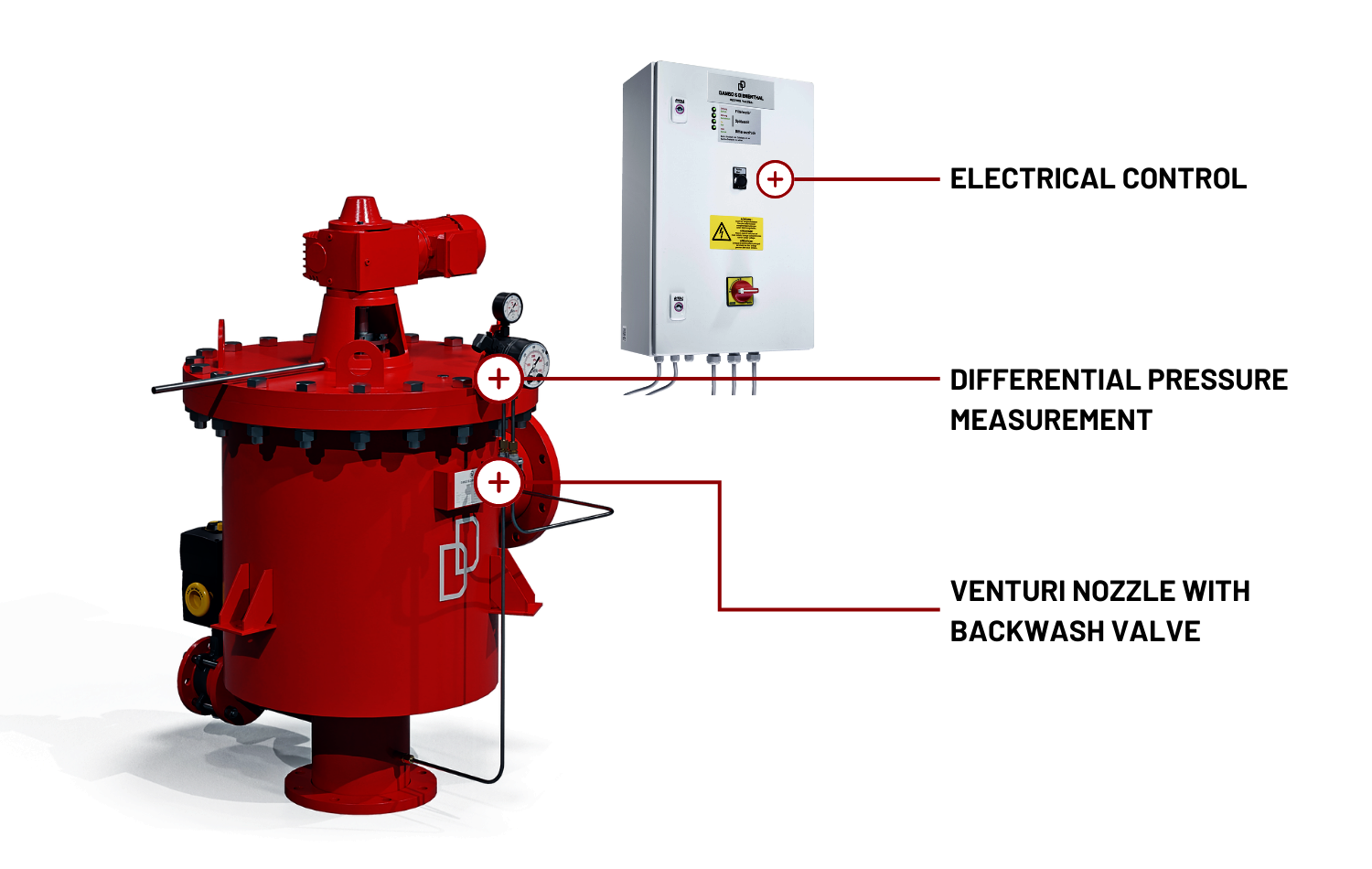

Electrical control system

The filter is controlled automatically depending on the time or differential pressure measurement. The system can send signals to the customer’s process control system (PCS) to report operational readiness, flushing processes, or faults.

![[Translate to English:] elektrische steuerung des JET Filters](/fileadmin/_processed_/b/e/csm_elektrische-steuerung_024cea25a7.jpg)

Differential pressure measurement

An optical display shows the operating and differential pressure. Two adjustable switching contacts can trigger filter flushing or activate an alarm message.

![[Translate to English:] Differenzsdruckmessungsgerät](/fileadmin/_processed_/b/8/csm_differenzdruckmessung_f6e10cd60e.jpg)

Venturi nozzle with backwash valve

The Venturi nozzle is designed to suit the customer’s operating conditions to adjust the required flushing water quantity and to prevent pressure fluctuations in the pipe network. Thanks to its efficiency, it reduces flushing water consumption by up to 70 %, halves disposal costs and protects the ecosystem at the point of use. The backwash valve can be controlled electrically or pneumatically as standard.

![[Translate to English:] Venturi-Drüse des JET Filters](/fileadmin/_processed_/b/9/csm_venturi-druese-mit-rueckspuelarmatur_897d6b67d1.jpg)

CONTACT

Are you interested in our product?

Then contact us via contact form, post@dds-filter.com or +49 271 401 4123.

We look forward to your inquiry!