![[Translate to English:] Plattenfilter](/fileadmin/_processed_/a/c/csm_Plattenfilter_a79b796d73.png)

Compact coarse filter for solid-liquid separation, available in automatic or manual designs

Plate filters from DANGO & DIENENTHAL offer efficient solid-liquid separation for industrial filtration and water treatment. Thanks to their robust design, easy installation and maintenance-friendly construction, they help reduce operating costs - making them the ideal filtration technology for solid-liquid particle separation.

Our high-performance water filters for industrial processes are available in various sizes and configurations and can be individually adapted. In addition to standardized filtration solutions, we offer customized filter systems for industrial applications. Our experts are happy to assist you in selecting the right filter system for your industrial application.

Request product

Download brochure now

The plate filter offers a separate collection area for separated solids, preventing direct impact on the filter element. Coarse and heavy particles are collected separately without clogging the filter element. This prevents blockages in the filter, extends operating times and reduces maintenance costs by up to 40 %.

Thanks to the housing cover with handle, the filter element can be replaced in less than 15 minutes - without complicated removal. The sophisticated design with a fixed dirt collection container and no moving parts also reduces wear. This saves you up to 90 % work, up to 20 % maintenance costs and around € 86,000 over the service life.

The low-wear design without moving parts and the robust monolithic cast iron housing with silicate-based cast skin ensure maximum resistance to external and media-induced influences. This extends the service life of your filter system, reduces operating costs by up to 30 % and halves disposal costs.

Individual Filtration solutions

Customized special solid-liquid separation solutions are developed for specific customer requirements. These may involve special materials, custom dimensions or application-specific adaptations. This ensures that the water filter can be perfectly integrated into the existing system and delivers optimal filtration performance for your industrial application.

Flexible cleaning

The plate filter can be cleaned manually or fully automatically, depending on the operating requirements. Manual cleaning is particularly cost-effective for simple applications, while automatic backwashing - controlled by a control system - ensures continuous filtration. This allows you to increase the operating efficiency of your company with maximum flexibility.

Comprehensive protection for sensitive systems

Our industrial water filter reliably protect industrial components such as plate heat exchangers, spray nozzles, pipe systems, pumps and microfiltration units. They contribute to environmental protection by safeguarding end products and water resources from contamination. Thanks to their high filtration performance, they are suitable for cooling water, river water, sea water, ballast water, process water, oils, emulsions and water infested by mussels. Even drinking and efluent water can be effectively treated. This ensures sustainable use and reliable solid-liquid separation.

WHY A BACKWASH FUNCTION?

A backwash function ensures continuous cleaning of the filter element and prevents clogging. Differential pressure measurement detects the degree of contamination and activates the backwash process when needed. This keeps filtration efficient at all times- without the need for manual intervention.

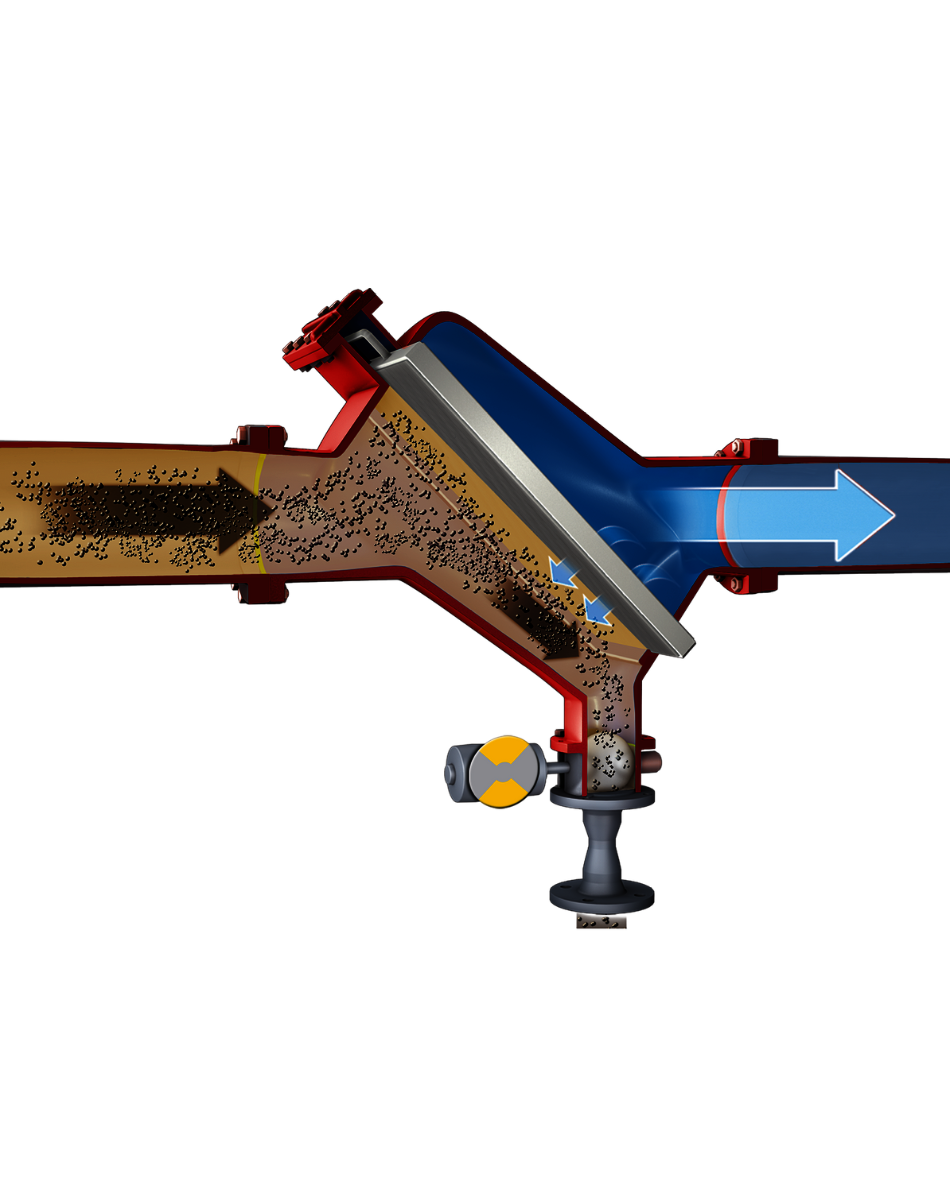

HOW DOES THE BACKWASH FUNCTION?

As soon as the defined differential pressure is reached, the motor-driven backwash valve opens. The high flow velocity flushes out dirt particles from the filter. According to Bernoulli’s law, a vacuum is created that draws clean water through the filter element in the opposite direction of filtration, removing accumulated particles. After 15–20 seconds, the process ends automatically – without interrupting coarse filtration.

Filter components

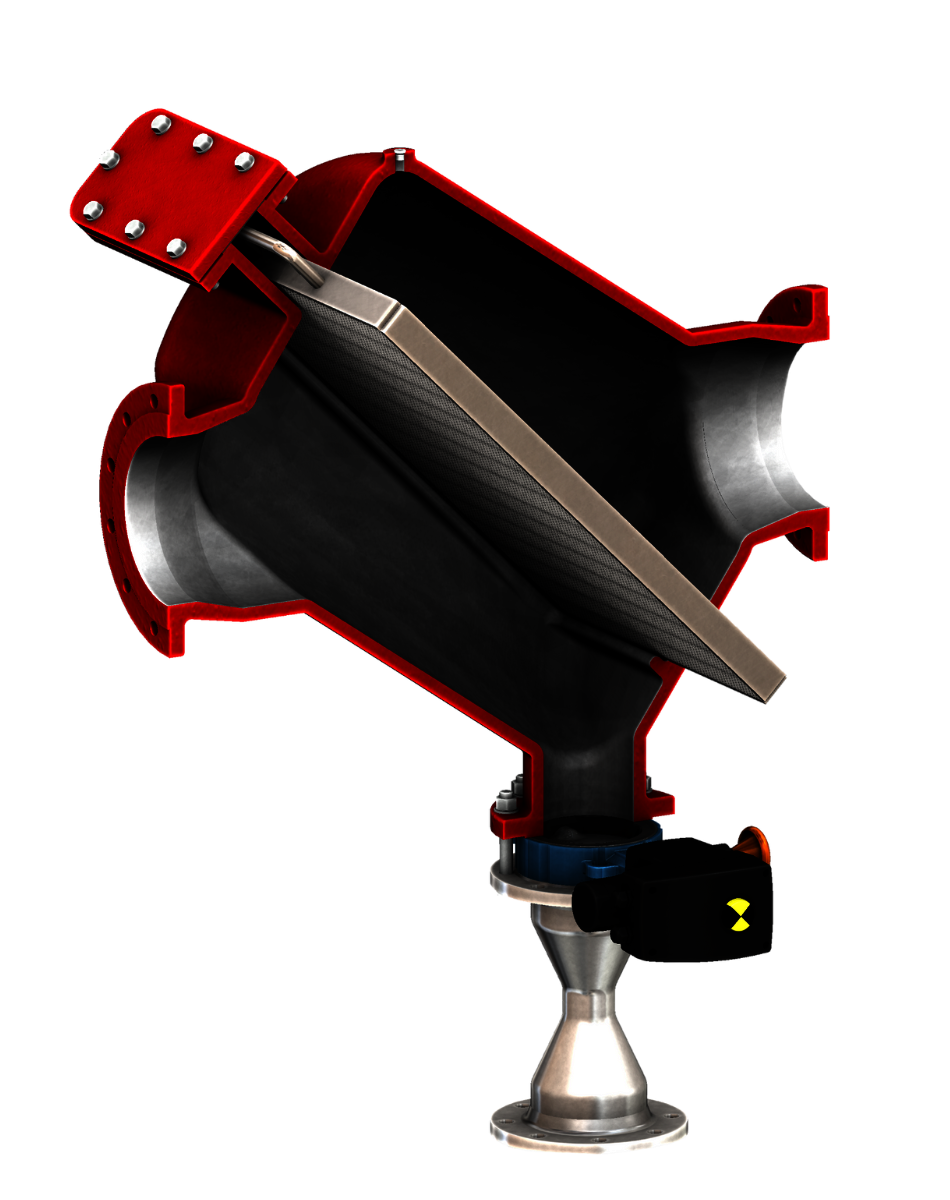

The Filter element

The filter element is made from a reinforced wedge-wire screen construction, allowing it to withstand even high differential pressures. Thanks to the integrated handle, it can be removed quickly and effortlessly from the filter housing during inspections. Depending on the requirements, the filter element can be designed in various stainless steel grades to ensure optimal durability and filtration performance.

![[Translate to English:] Filterelment des Plattenfilters](/fileadmin/_processed_/f/c/csm_filterelement-plattenfilter_c7dfee641f.png)

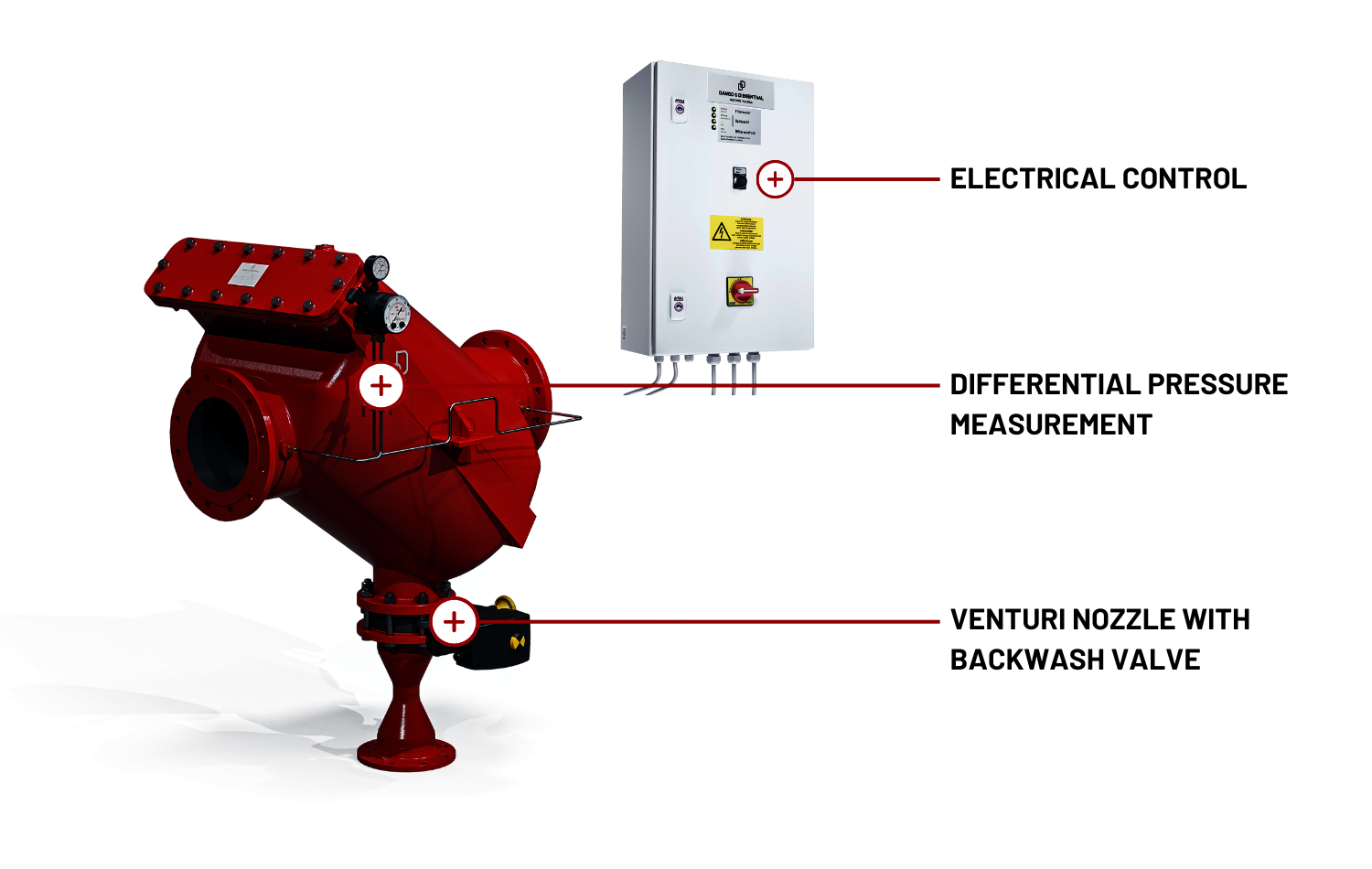

Electrical control

The backwash process is initiated automatically – either time-controlled or based on the differential pressure. This enables fully automatic filter operation. The standard control system communicates with the customer's process control system (PCS) and provides the following signals:

- Collective fault

- Operational readiness

- Filter flushing mode

- External triggering of filter backwash

- External release of the filter backwash

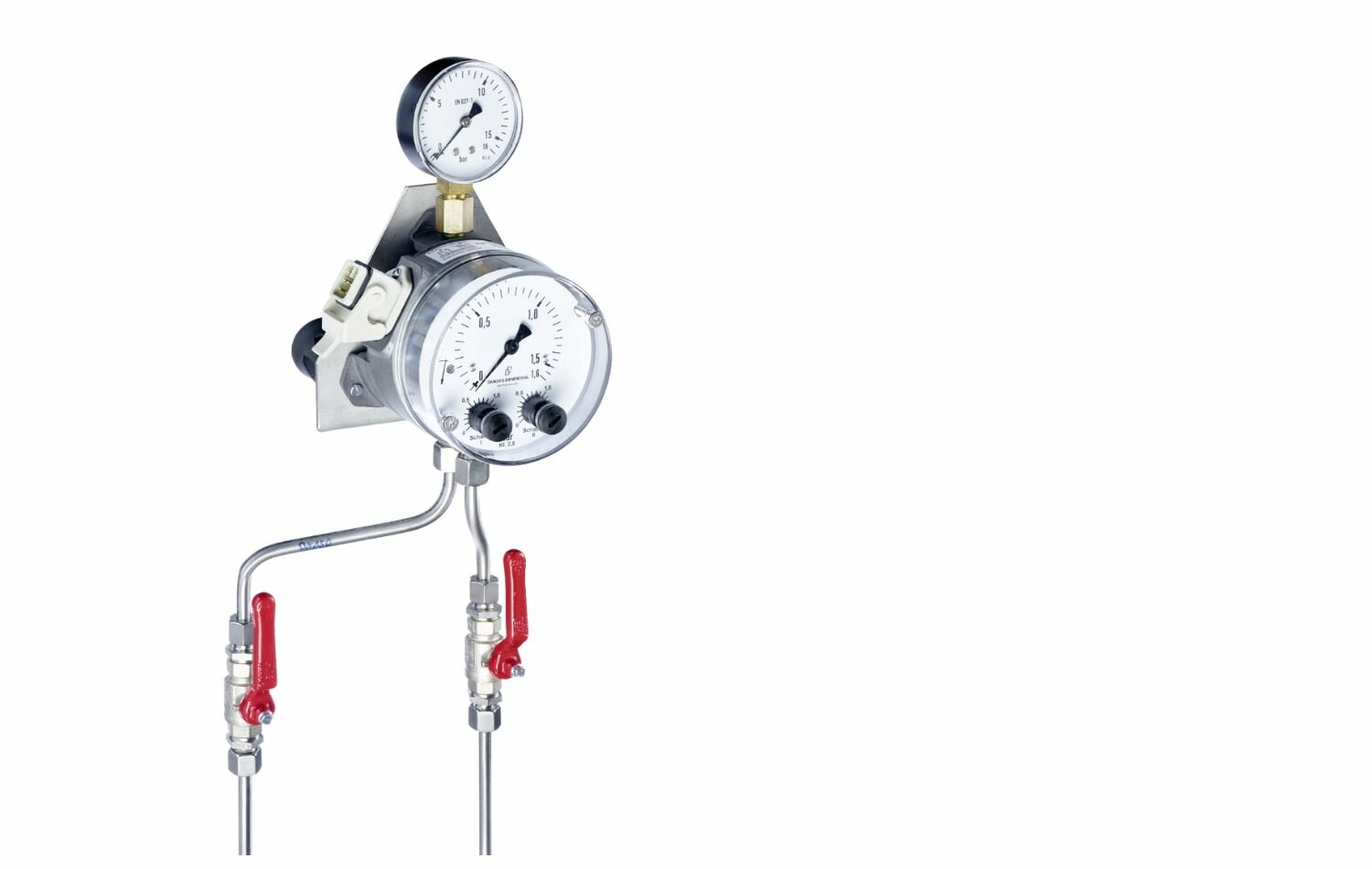

Differential pressure measurement

The very low differential pressure in clean condition enables the protected installation of a pump on the suction side - without pre-filtration. Coarse particles are kept out, which minimizes wear on the pump. An integrated differential pressure measurement with visual display and freely adjustable switching contacts also ensures precise monitoring, automatic flushing and an alarm signal in the event of critical pressure conditions. This extends the service life of your pump by up to 5 years and increases the efficiency of your system.

Venturi nozzle with backwash valve

The Venturi nozzle is specifically tailored to the customer’s operating conditions to ensure an optimal flushing water quantity and to avoid pressure fluctuations in the pipe network. The backwash device is equipped as standard with an electric or pneumatic actuator, ensuring precise and reliable control of the backwash process.

CONTACT

Are you interested in our product?

Then contact us via contact form, post@dds-filter.com or +49 271 401 4123.

We look forward to your inquiry!

![[Translate to English:] Plattenfilter im Industriegebrauch](/fileadmin/_processed_/f/c/csm_plattenfilter-03_da2815d39e.jpg)

![[Translate to English:] Plattenfilter im Industriegebrauch](/fileadmin/_processed_/e/2/csm_plattenfilter-02_736089c2cf.jpg)

![[Translate to English:] Plattenfilter im Industriegebrauch](/fileadmin/_processed_/6/c/csm_plattenfilter-01_8475daa8b3.jpg)