Efficient industrial filtration technology for reliable solid-liquid separation

With an innovative, patented design, the JET filter is a highly developed industrial inline filter for the separation of solids from liquids. The low-wear filter offers maximum reliability and efficiency in the filtration process, even under demanding conditions. Its water filtration performance enables high throughput rates with minimal flushing water losses.

Thanks to the flexible inline design with any installation position - horizontal or vertical - the industrial water filter can be integrated into almost any piping system to save space without any time-consuming adaptations. This saves 30-40 % of the conversion planning and installation costs and guarantees simple, layout-compatible integration.

Request product

Download brochure now

The JET filter offers a cleaning speed of up to 10 m/s and ensures 100% cleaning of the entire filter surface - even with changing dirt loads. The constantly high cleaning performance enables consistent filtration efficiency.

This increases your productivity by up to 20 %, prevents production interruptions and ensures permanently stable operational reliability. At the same time, the sophisticated design and low rinsing water consumption minimize resource requirements and increase overall operating efficiency.

Thanks to the flexible inline design, our industrial filter can be quickly and easily integrated into existing systems - horizontally or vertically. There is no need for time-consuming pipe relocations, which saves up to 40 % on installation costs and shortens commissioning by up to 2 days.

Customized adaptations also allow integration into complex installation situations without conversions - for faster amortization of the overall project.

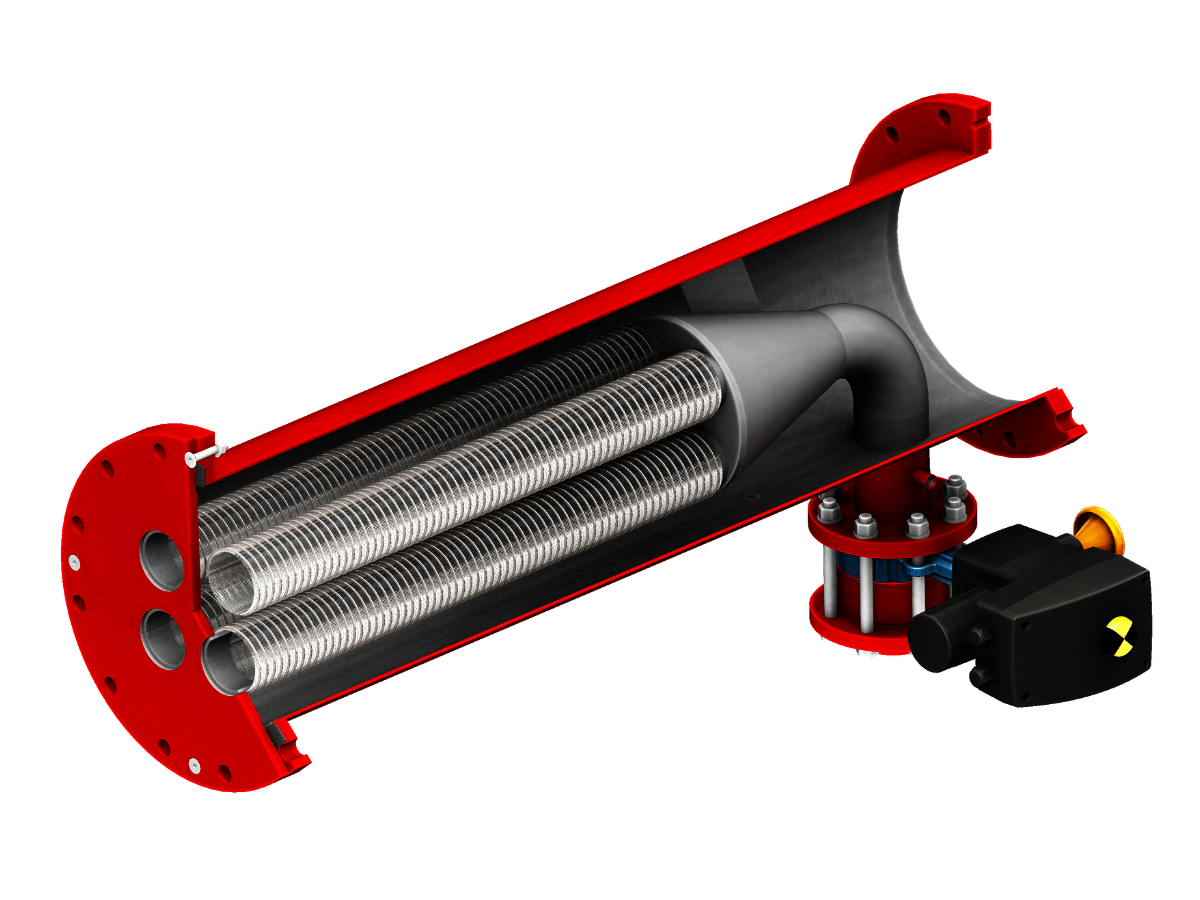

The filter elements are made of high-quality stainless steel and the industrial filter has no moving parts. Instead of a rotating backwash arm, the D&D water filter relies on a dirt collection container with a side outlet - this minimizes mechanical wear and significantly reduces maintenance costs.

This reduces maintenance and overhaul costs by 15-20 % over the service life of the filter, increases system availability and avoids unplanned downtimes.

Variety of materials and adaptability of the water filter

The JET filter is available in steel, stainless steel, GRP, and plastic and can be adapted to meet the specific requirements of any industry. The industrial filter offers full performance in any environment. This gives you security when selecting the right material for your operating conditions. Customized special solutions and a robust design make it the optimal choice for demanding water filter systems in various industries.

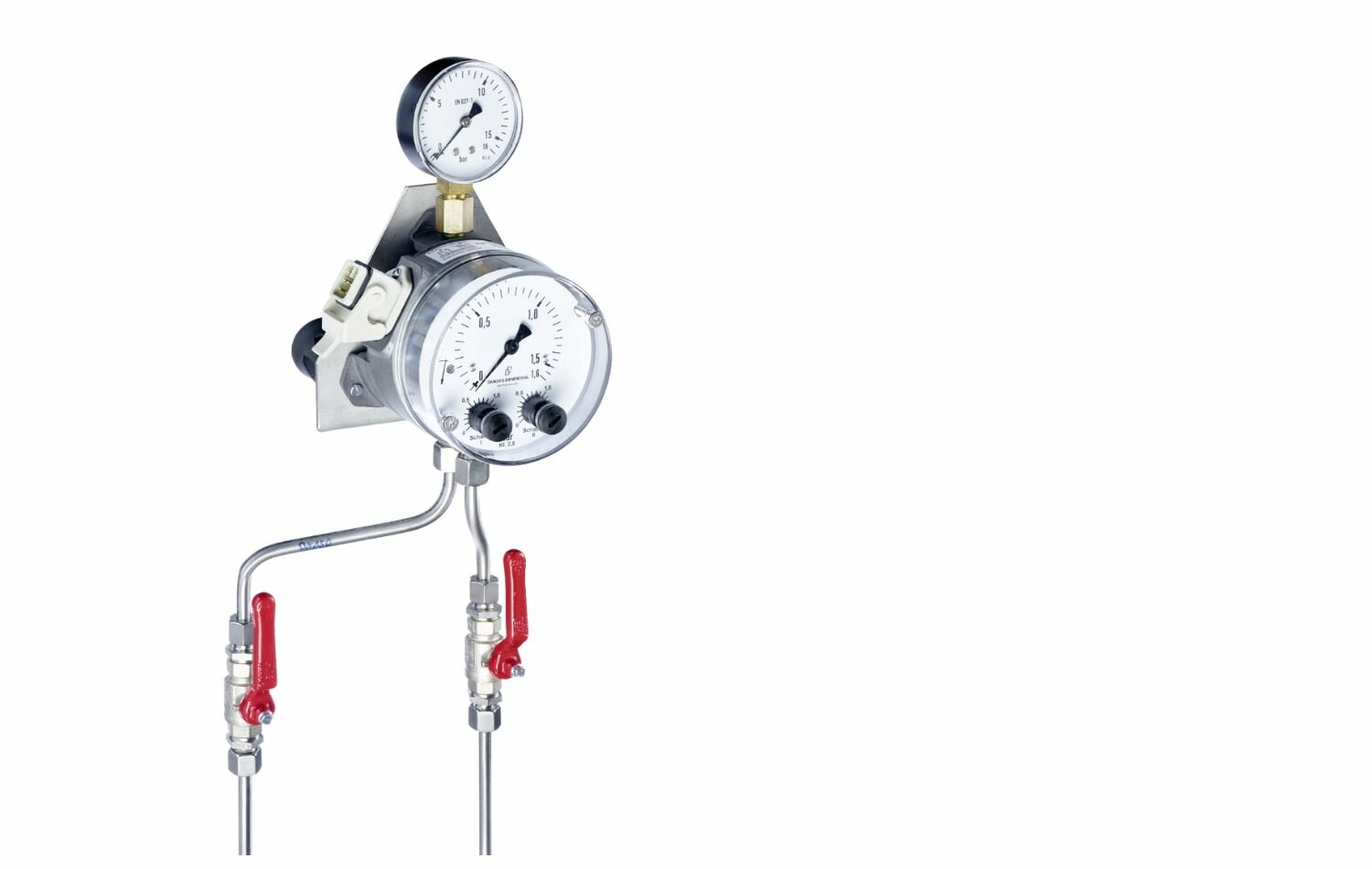

Stable differential pressure: reliability throughout operation

The differential pressure remains constant during operation, which ensures stability in piping and process systems. This feature makes our automatic filter particularly reliable for sensitive applications with high demands on pressure stability.

![[Translate to English:] Differenzsdruckmessgerät des JET Filters](/fileadmin/_processed_/d/1/csm_jet-filter-differenzdruckmessung_949db05e4c.png)

Comprehensive protection for industrial systems and the environment

The JET filter protects a wide range of sensitive system components such as plate heat exchangers, pumps, spray nozzles, piping systems, and mechanical seals from damage and contamination. The filter also contributes to environmental protection by removing pollutants from process media and minimizing water pollution.

Versatile applications for a wide range of media

Our automatic filter is designed for numerous media, including cooling water, river water, sea water, ballast water, process water, and drinking water. It even offers reliable filtering results for demanding applications such as sinter and scale water, water infested with mussel larvae, oils, emulsions, and drain water. This versatility makes it the ideal choice for a wide variety of industries and applications.

WHY A BACKWASH FUNCTION?

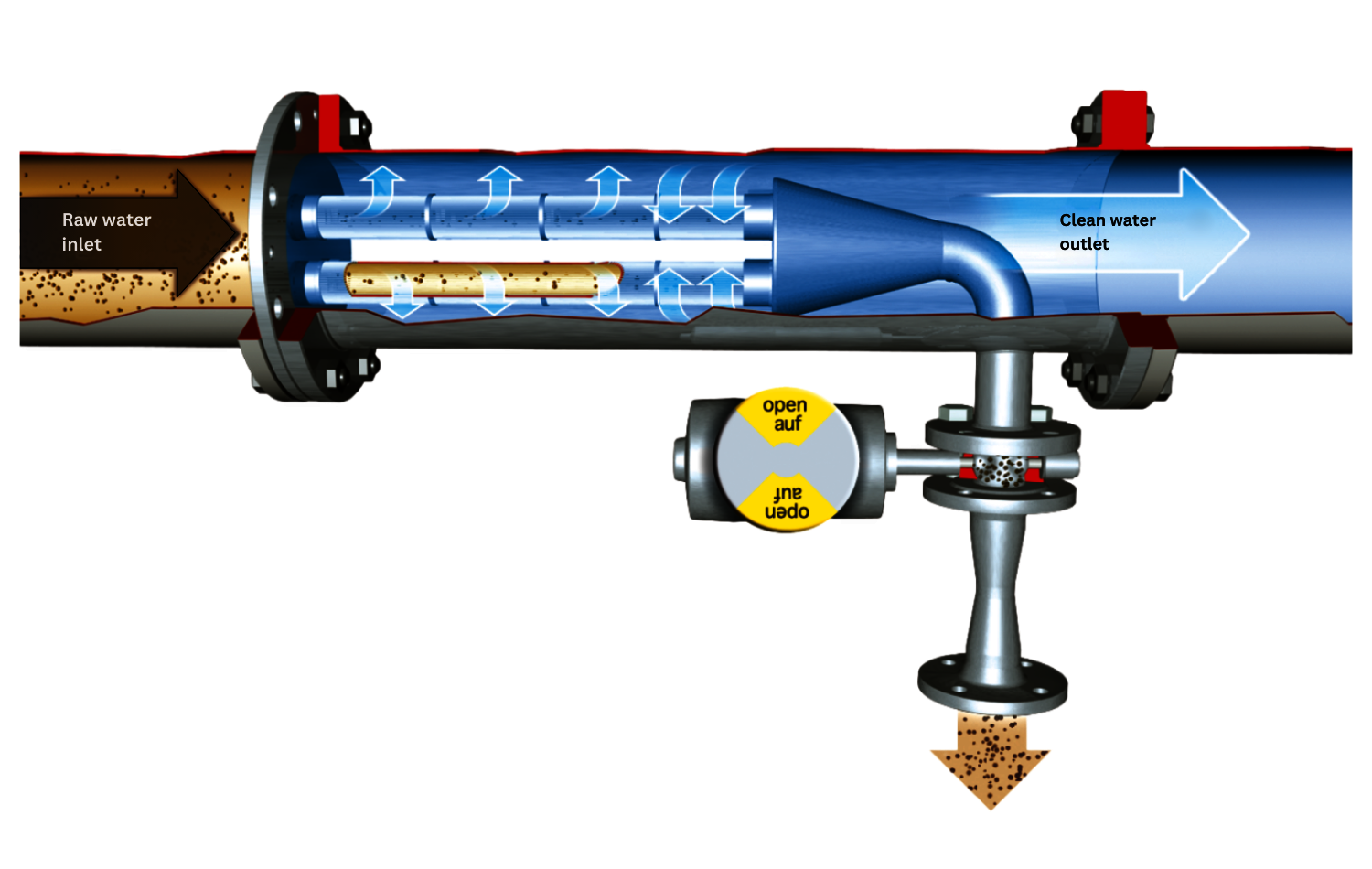

The backwash function is necessary to effectively clean the filter elements of accumulated dirt particles and ensure their optimum functionality. It ensures that the automatic filter works efficiently at all times without having to interrupt operation.

HOW DOES THE BACKWASH FUNCTION WORK?

At the start of filter cleaning, the motor-driven backwash valve opens. A small amount of the raw water then flows through the backwash opening. This flushes dirt particles out of the filter. The axial flow velocity in the filter elements increases to up to 10 m/s, supporting the cleaning process. A vacuum also ensures that clean water is flushed from the outside to the inside. The backwash valve closes automatically after 10-20 seconds. Filtration remains uninterrupted during the entire process.

This video illustrates the individual steps of the filtration process of our JET Filter.

From the entry of the raw water to the exit of the purified water, it shows how the automatic backwash function works without interrupting the filtration process.

During backwashing, a small amount of the raw water flows through the backwash opening, removing dirt particles from the dirt collection container. The axial flow velocity in the filter elements increases to up to 10 m/s, supporting the cleaning process while guaranteeing that backwash proceeds from the outside to the inside with clean water due to the generated vacuum.

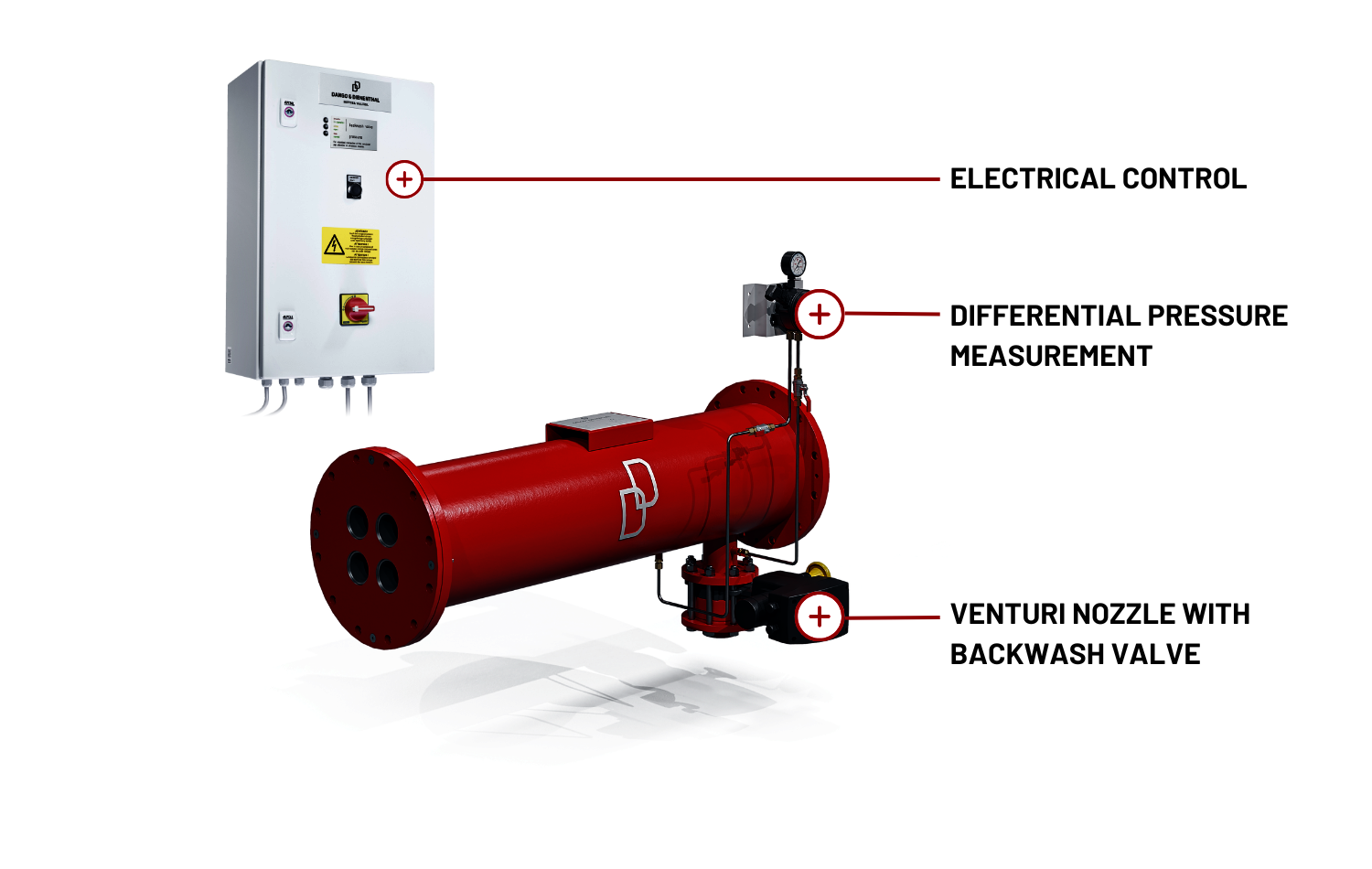

Electrical control system

The JET filter's electrical control system enables fully automatic operation by initiating the backwash process based on time or differential pressure. It ensures smooth signal exchange with the customer's process control system (PCS), including messages such as “collective fault”, “operational readiness” and “filter in flushing mode”. In addition, “external triggering of filter backwash” and “external release of filter backwash” can be easily integrated, further increasing the efficiency and reliability of the system.

![[Translate to English:] elektrische steuerung des JET Filters](/fileadmin/_processed_/b/e/csm_elektrische-steuerung_024cea25a7.jpg)

Differential pressure measurement

The differential pressure measurement in our automatic filter offers precise monitoring of the operating pressure upstream of the filter and the differential pressure. With two freely adjustable switching contacts, it enables flexible control, including the start of filter flushing and the display of alarm messages.

Venturi nozzle with backwash valve

The Venturi nozzle is designed to suit the customer's operating conditions to adjust the required flushing water quantity and to prevent pressure fluctuations in the pipe network. The backwash valve is equipped with an electric or pneumatic actuator as standard.

The result: Minimal rinse water loss - you save up to 70 % of rinse water consumption, reduce your disposal costs by half and protect the ecosystem at the place of use.

![[Translate to English:] Venturi-Drüse des JET Filters](/fileadmin/_processed_/b/9/csm_venturi-druese-mit-rueckspuelarmatur_897d6b67d1.jpg)

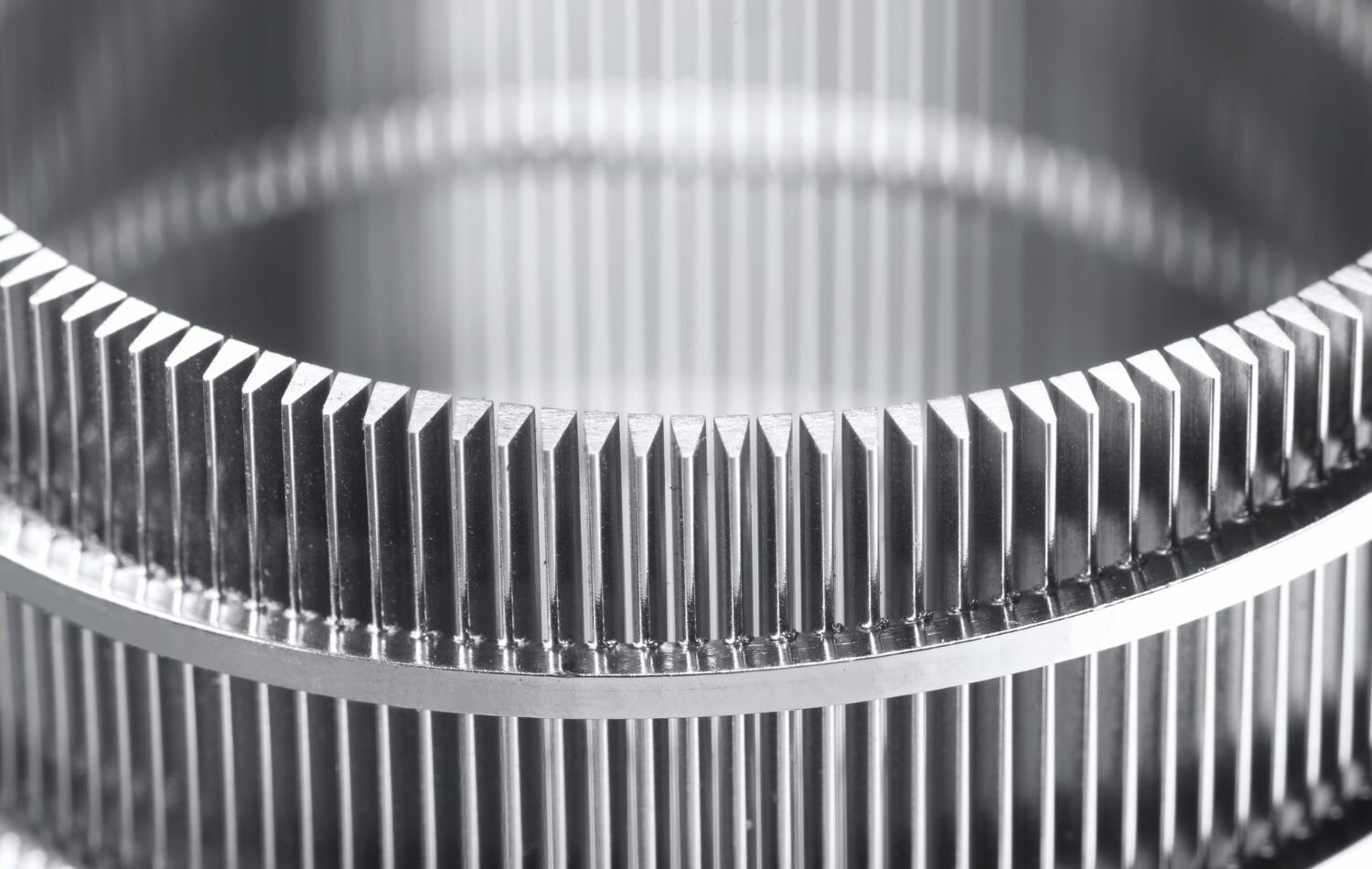

Filter element

The filter element of the JET filter is made of robust stainless steel and ensures efficient cleaning and long-lasting filter performance thanks to its screen cylinders with axial gaps. Manufactured from welded triangular rods, the filter cartridges are available in various stainless steel grades and with a filter finenesses starting from 50 μm - ideal for filtering large volumes of water.

CONTACT

Are you interested in our product?

Then contact us via contact form, post@dds-filter.com or +49 271 401 4123.

We look forward to your inquiry!