Water treatment with industrial filters

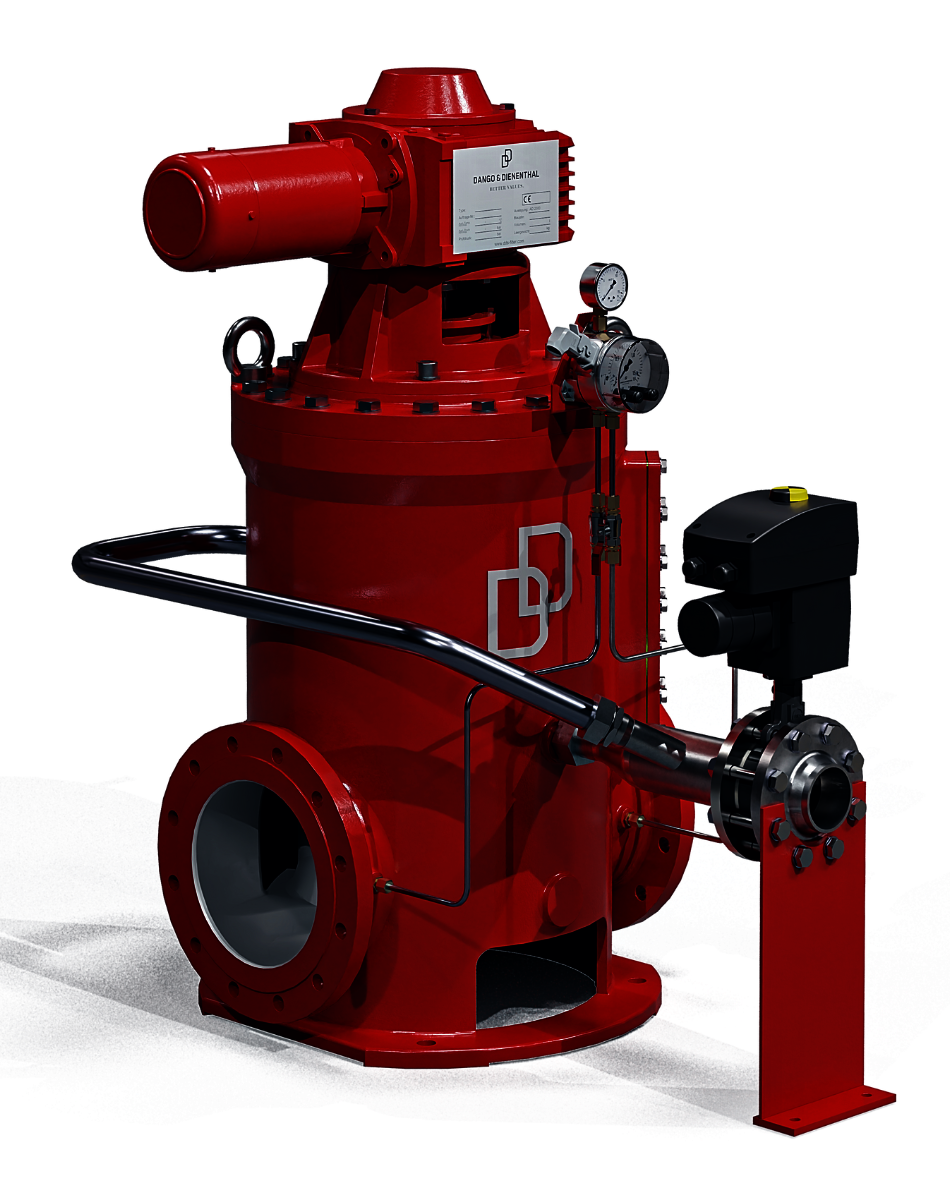

Reliable solid-liquid separation of process water without interruptions with DANGO & DIENENTHAL automatic filters

NOT SURE WHICH OF OUR PRODUCTS IS RIGHT FOR YOU?

Our experts will be happy to help you find the right product for your requirements.

Efficient filtration solutions

Whether process water treatment, cooling circuits or waste water treatment - our industrial filters provide reliable water treatment and ensure the trouble-free operation of your system.

Thanks to minimized maintenance requirements, reduced downtimes and optimized filtration performance, they sustainably reduce your operating costs.

EXTREMELY ROBUST AUTOMATIC FILTER FOR HIGH VOLUME FLOWS

The Filterautomat is a fully automatic pressure filter system for continuous solid-liquid separation in industrial applications with a high volume of dirt. As an automatic backwash filter, it cleans itself by means of differential pressure monitoring - without interrupting filtration operation.

The modular design enables quick integration into existing or new systems. Ideal for water treatment of industrial water and automated processes in process water treatment.

More about the automatic filter Request product

ROBUST INDUSTRIAL FILTER FOR CHANGING OPERATING CONDITIONS

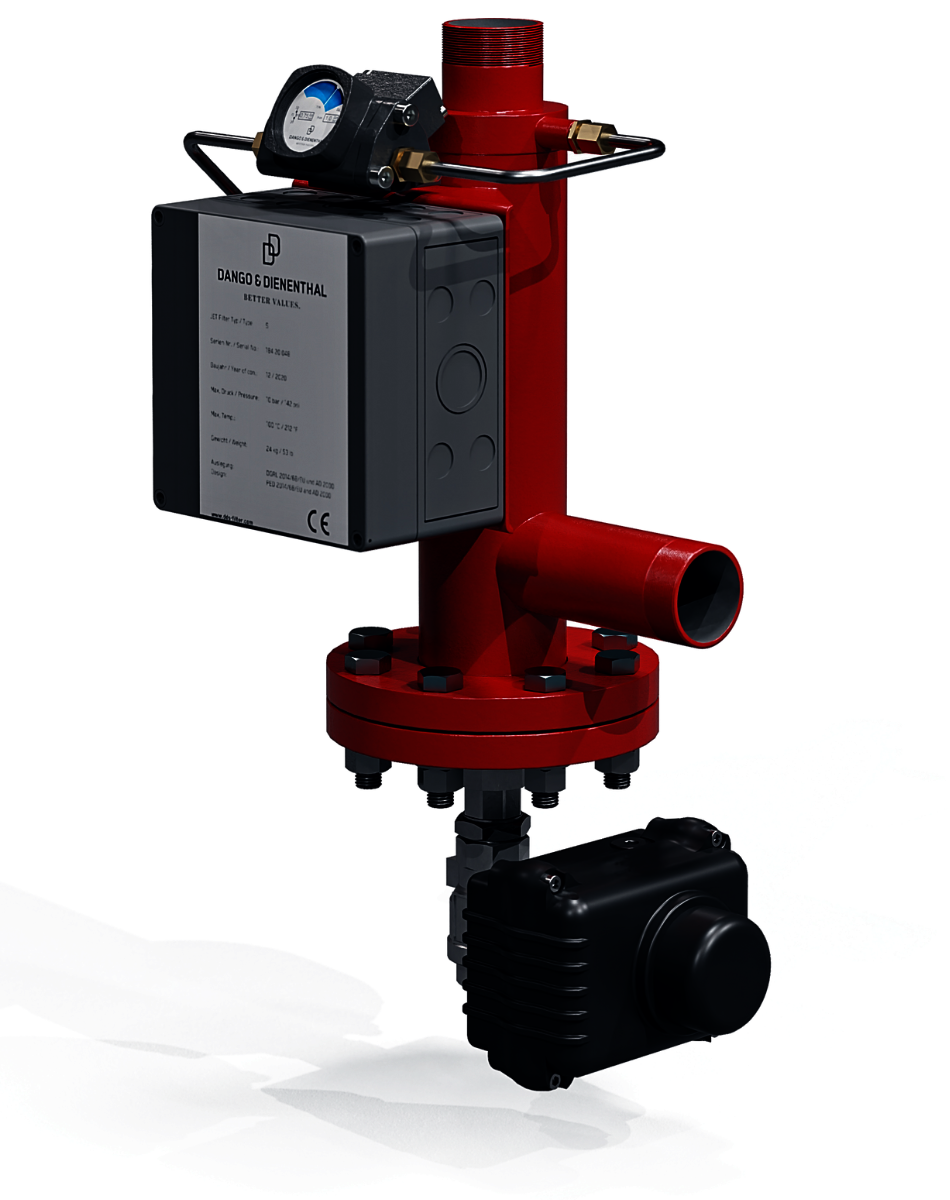

The JET filter is an automatic backwash filter for reliable solid-liquid separation at medium flow rates. The integrated backwash function is triggered as required via differential pressure or time control - without interrupting the filtration process.

Thanks to its compact design and high material resistance, the JET filter is particularly suitable for industrial water treatment and process water treatment, even with limited space and variable loads.

More about the JET Filter Request product

COMPACT INDUSTRIAL FILTER FOR LIMITED INSTALLATION SPACE

The JET Filter S is a compact automatic backwash filter with replaceable filter cartridges - designed for solid-liquid separation in confined spaces. The maintenance-friendly design allows cartridges to be changed without tools, while the automatic backwash function ensures uninterrupted operation.

Ideally suited for water treatment of industrial water, retrofitting existing systems and for small to medium volume flows in waste water and process water treatment.

More about JET Filter S Request product

Areas of application for industrial filters

FOCUS ON INDUSTRIAL FILTERS:

RISKS DUE TO INEFFICIENT FILTRATION

Reliable water treatment is essential in order to operate systems efficiently and trouble-free. Without suitable filtration solutions for industrial applications, dirt particles and deposits can pollute the entire technology - from pipes to machines.

The result: high maintenance costs, unplanned downtime and rising operating costs. Especially in process water treatment and wastewater treatment, inefficient water treatment systems quickly lead to problems that impair economic efficiency - for example due to inadequate solid-liquid separation or unsuitable filter solutions in industrial water treatment.

Request industrial filter

Typical risks of inadequate filtration systems

- Maintenance costs increase as filters have to be cleaned manually.

- At the same time, the quality of the process watersuffers, which can impair production and jeopardize product quality.

- In many cases, inadequate filtration solutions even leadto unplanned downtime - with considerable consequential costs.

Despite these risks, many companies continue to rely on simple, non-automated filtration systems. Modern filtration systems such as automatic backwash filters enable continuous, efficient process water treatment - with significantly lower personnel costs, stable filtration performance and greater operational reliability.

Request product

SHAPE BETTER VALUES

CLOSER. BETTER. SIMPLER.

We make sure that you get the filter that is perfectly tailored to your application. In our technical office, the filter is designed according to your operating parameters. Our product is thus explicitly adapted to your application.

Experienced partner

All filters from DANGO & DIENENTHAL are processed by specially trained and regularly trained personnel. Our teams in both mechanical production and assembly have extensive know-how.

The team at your side

If you require personnel for on-site training or maintenance, please contact us. Our employees will be happy to support you.

Certified testing

Our certified quality management system enables seamless monitoring and control of all production steps. Errors are detected and rectified at an early stage, enabling us to offer you a high level of quality.

Best production conditions

Production has been taking place at our plant in Siegen, Germany, since 1941. Constantly improved, state-of-the-art machinery and modern factory buildings provide an environment in which high-quality products can be created for our customers.