![[Translate to English:] [Translate to English:] Aluminiumherstellung](/fileadmin/_processed_/a/2/csm_factory-2639751_1920_3b33fca854.jpg)

Table of Contents

WATER TREATMENT IN THE ALUMINUM INDUSTRY

The production of aluminum involves high temperatures and energy-intensive processes. To ensure the reliable operation of equipment and heat exchangers, continuous cooling is required. Cooling and process water therefore form an integral part of aluminium production processes.

In the aluminum industry, natural water sources such as rainwater or river water are often used for this purpose. However, these water sources contain dirt particles and sediments which, without suitable treatment, can lead to deposits, increased maintenance requirements and reduced performance.

This article describes the aluminum production process, the importance of water and cooling systems, and the role of filtration in water treatment. A practical example illustrates how filtration can help stabilise plant operation and reduce maintenance effort.

AT A GLANCE

- Due to high process temperatures, aluminum production requires a continuously reliable heat removal via water-based cooling systems.

- The use of untreated rainwater or river water can lead to deposits, increased maintenance effort and operational restrictions due to fluctuating solids loads.

- Filtration systems ensure consistent water quality, reduce downtime and make a measurable contribution to plant efficiency and availability.

PRODUCTION AND EXTRACTION OF PURE ALUMINUM

When aluminum is extracted from natural raw materials, this is referred to as the production of so-called primary aluminum. This aluminum is used, for example, in the automotive or packaging industries. Its range of applications is virtually unlimited. The production and extraction of pure aluminum involves several chemical and thermal processes that are closely coordinated.

Aluminum does not occur naturally in pure form, but is mainly bound in bauxite ore. This ore is usually mined close to the surface and serves as the raw material for aluminum production. Typically, around four to five tonnes of bauxite are required to produce one tonne of aluminium.

The production of aluminum oxide (alumina) from bauxite is carried out using the Bayer process. In this process, the ore is chemically treated with caustic soda at elevated temperatures, dissolving the aluminum-bearing components while insoluble residues are separated.

In a first step, the bauxite is crushed and chemically treated in refineries to produce aluminum oxide (alumina). Undesirable components such as iron, silicon or titanium are removed. This process already requires high temperatures as well as the use of water and chemicals.

In the subsequent smelting process, the aluminum oxide is converted into pure aluminum at very high temperatures and with the use of large amounts of electrical energy. This electrochemical process produces aluminum with a purity of around 99.8%.

Aluminum production is therefore extremely energy- and heat-intensive, which is why reliable and suitable liquid cooling of the equipment plays a central role throughout the entire production process.

The Hall-Héroult process is the second key step in aluminum production following the Bayer process. In this process, the previously produced aluminum oxide is dissolved in molten cryolite and converted into metallic aluminum using electrical current.

WATER AND COOLING PROCESSES IN ALUMINUM PRODUCTION

Aluminum production is characterised by numerous thermal processes that generate consistently high temperatures. Both during bauxite refining and the subsequent smelting process, equipment, machinery and heat exchangers must be reliably cooled to ensure safe and trouble-free operation.

Cooling and process water play a central role in this context. They are used to dissipate heat from production processes, protect equipment from overheating and ensure stable process conditions. Without continuous cooling, stable production operations would not be possible.

Depending on location and availability, different water sources are used. In addition to freshwater, rainwater or river water is frequently utilised in the aluminum industry. These natural waters are cost-effective and resource-efficient, but they also carry varying levels of contamination that must be considered during water treatment.

CHALLENGES WHEN USING NATURAL WATER

In aluminum production, natural water such as rainwater or river water is often used as a cooling medium. These water sources typically contain dirt particles, sediments, organic matter and suspended solids, the composition and concentration of which can vary significantly depending on weather conditions or seasons.

If these contaminants enter the cooling circuit, they can settle in heat exchangers, pipelines and other plant components. This leads to reduced heat transfer performance and increased maintenance requirements.

Without appropriate treatment, the use of natural water can impair the reliability of plant operation and negatively affect productivity through performance losses or unplanned downtime.

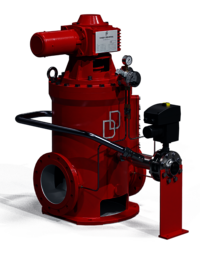

Filterautomat

Are you planning a filtration solution for your aluminum production, or would you like to replace or optimize an existing filter?

We provide advice on suitable filtration technology, system design and possible adaptations to existing installation conditions.

We would be pleased to discuss your requirements in a personal conversation.

FILTRATION IN WATER TREATMENT FOR THE ALUMINUM INDUSTRY

To safely use natural water in cooling and process circuits, water filtration is essential. It removes dirt particles and sediments before they reach heat exchangers or equipment and cause deposits. This ensures stable operating conditions and consistent cooling performance.

Unlike chemical treatment methods, filtration operates without the use of additives. Chemical methods are often used only as supplementary measures and involve additional effort. Filtration, on the other hand, enables the continuous and controlled removal of solid contaminants and is therefore particularly well suited for industrial cooling water systems in the aluminum industry.

PRACTICAL EXAMPLE OF FILTRATION IN THE ALUMINUM INDUSTRY

DANGO & DIENENTHAL Filtertechnik supported a well-known aluminum producer in France in optimising its cooling water supply for high-temperature applications. For cooling purposes, collected rainwater combined with river water is used and transported via pipelines into the production facility, where it is circulated through heat exchangers.

To ensure reliable heat dissipation and prevent blockages in the heat exchangers, filtration of the natural water was required. Two automatic backwash filters of type DDF DN 500 were installed on site. These filters are designed for heavily contaminated fluids and achieve backwash velocities of up to 10 m/s, ensuring that the required water quality is continuously maintained.

As a result of using these automatic filters, maintenance intervals for the heat exchangers were significantly extended. Consequently, maintenance-related costs were reduced while the productivity of aluminum production was sustainably increased.

CONCLUSION

Aluminum production is an energy- and heat-intensive process in which reliable cooling of equipment plays a crucial role. Cooling and process water are indispensable for stable production operations.

The use of natural water such as rainwater or river water offers economic and ecological advantages, but also places specific demands on water quality. Without suitable treatment, dirt particles and sediments can impair the performance of heat exchangers and equipment, leading to increased maintenance effort and productivity losses.

In this context, filtration proves to be a key solution. It enables the controlled removal of solid contaminants, supports reliable operation of cooling water systems and helps extend maintenance intervals while reducing operating costs. The practical example from DANGO & DIENENTHAL Filtertechnik demonstrates how the targeted use of suitable filtration technology can sustainably improve both operational reliability and efficiency in aluminum production.

FAQ ON ALUMINUM PRODUCTION AND FILTRATION TECHNOLOGY

Cooling and process water directly affect the performance of heat exchangers and equipment. Contaminated water can cause deposits that reduce heat transfer efficiency and increase maintenance requirements.

Natural water often contains varying amounts of dirt particles and sediments. If these enter the cooling circuit without filtration, blockages, performance losses and unplanned downtime may occur.

These are two separate, sequential processes in aluminum production: the Bayer process produces aluminum oxide (alumina) from bauxite, which is then converted into metallic aluminum in the Hall-Héroult process by electrolysis in molten cryolite.

Filtration removes contaminants directly from the water and operates without chemical additives. This ensures consistent water quality and helps maintain stable operation of cooling water systems. Contact us if you are planning a filtration solution for your aluminum cooling water system or would like to optimize existing installations in terms of water quality.

The backwash function automatically cleans the filter element of accumulated solids without interrupting the filtration process – as implemented, for example, in the Filterautomat from DANGO & DIENENTHAL Filtertechnik. This keeps the filter surface permanently clear, prevents blockages and rising differential pressure, and ensures consistent filtration performance as well as long filter service life.