Table of Contents

FILTRATION IN PUMPED-STORAGE POWER PLANTS – ENSURING RELIABLE PROTECTION FOR KEY COMPONENTS

The reliable operation of hydroelectric power plants depends heavily on protecting their sensitive components. Ball valves, turbines, and other key parts require clean water – even the smallest particles or traces of rust can cause wear and disrupt operations. Targeted filtration therefore plays a central role: it protects components from contamination, extends maintenance intervals, and ensures the plants operate stably and reliably.

In this blog post, you will learn how pumped-storage power plants work and the role of ball valves as critical components. We will then show how targeted filtration protects these parts, reduces wear, and prolongs maintenance intervals.

AT A GLANCE

- Pumped storage power plants store surplus electrical energy and release it when required. Water flow and turbine operation are precisely controlled during both generating and pumping modes.

- Ball valves are critical components that regulate water flow, protect turbines and enable safe and flexible plant operation.

- Efficient filtration systems clean the water supplying the ball valves, reduce wear on sealing surfaces, extend maintenance intervals and increase overall plant availability.

HOW PUMPED-STORAGE POWER PLANTS WORK

Alongside electricity generation from fossil fuels, the share of solar and wind energy in the power grid is steadily increasing. To balance the fluctuations caused by sunlight and wind, flexible energy storage solutions are becoming increasingly important. Pumped-storage power plants help by using excess energy to pump water into an elevated reservoir.

When needed, this water can be released again to generate electricity. When electricity demand is high, water flows from the upper reservoir through pipes into the lower reservoir, driving turbines that generate electrical power. Conversely, when there is abundant solar or wind energy, the water is pumped back up to the upper reservoir. Modern plants often operate multiple turbines simultaneously, allowing them to respond flexibly to electricity demand.

Pumped storage power plants can switch from standstill to turbine operation within just a few minutes, allowing them to respond very quickly to fluctuations in the power grid. This rapid start up capability makes them particularly valuable when additional capacity is required at short notice.

The power plant itself is often located in an underground cavern, housing turbines, generators, and pumps. Large ball valves installed in the connecting pipes regulate the flow of water to the turbines, generators, and pumps. They adjust the flow depending on whether electricity is being generated or the water is being pumped back to the reservoir.

In this way, a pumped-storage power plant works much like a giant battery: energy is stored when it is abundant and released when needed. With an efficiency of around 80 %, pumped storage is one of the most effective ways to store electrical energy.

BALL VALVES AS CRUCIAL COMPONENTS IN PUMPED-STORAGE POWER PLANTS

Ball valves are key components in every pumped-storage power plant. Positioned before the turbines, they regulate the flow of water so that the turbines operate only when needed. As long as the ball valve is closed, the water flow is blocked. A small bypass allows the pipeline to fill slowly before the turbine starts. Once the pressure on both sides is equalized, the ball valve opens fully, letting water flow freely onto the turbine to generate electricity.

For the safe operation of the ball valve, clean, filtered water is essential. It ensures that the sealing plate at the valve seat is properly controlled when the valve is closed. Even the smallest particles or traces of rust in the water can damage the metallic sealing surfaces and compromise the safe function of the ball valve.

Ball valves serve multiple purposes. They ensure tight seals, prevent leaks, and reduce wear on the turbines. They act as a safety mechanism, able to quickly stop the water flow in emergencies or during sudden shutdowns and allow individual pipes to be isolated for maintenance while other turbines continue operating. In addition, they help maintain stable pressure in the pipelines and precisely control the flow of water.

Thanks to these properties, ball valves are indispensable for the safe and flexible operation of a pumped-storage power plant. They ensure that energy can be reliably stored and released when needed.

EFFICIENT PROTECTION OF BALL VALVES THROUGH A FILTER SYSTEM

A German operator of several hydroelectric power plants faced the problem that the water supplying the ball valves was partly contaminated with rust and coarse particles due to the previously used cast iron filter. As a result, the valve water could not be adequately cleaned, and the direct protection of the metallic sealing surfaces was not guaranteed. Such impurities can damage the sealing surfaces and compromise the safe operation of the ball valves. To ensure the reliability of the turbines and the smooth operation of the plants, a more efficient filter was therefore required.

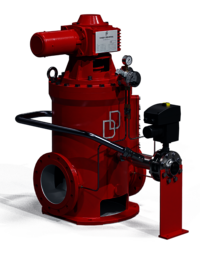

DANGO & DIENENTHAL Filtration subsequently developed a new stainless steel filter system. A major advantage of this filter is that it has the same dimensions as the old cast iron filter, allowing installation on-site without costly modifications.

The new filter system offers several significant benefits. Firstly, the stainless steel material ensures a much longer service life and minimizes the risk of corrosion. Secondly, the filter reliably protects the ball valves from dirt particles, reducing wear. This leads to longer maintenance intervals, which in turn increases the availability of the power plant facilities.

Filterautomat

Are you planning a filtration solution for a pumped storage power plant, or are you looking to replace or optimise an existing filter system?

We provide advice on suitable filtration technology, system design and possible adaptations to existing installation conditions.

We would be pleased to discuss your requirements in a personal conversation.

CONCLUSION

Pumped-storage power plants balance fluctuations in the power grid by storing excess energy and releasing it when needed. Crucial for safe and smooth operation are ball valves, which precisely control the flow of water and protect the turbines.

A practical example of targeted optimization is the stainless steel filter system from DANGO & DIENENTHAL Filtration, used by an operator of several hydroelectric power plants. It reliably protects the ball valves from contamination, reduces wear, and extends maintenance intervals, making plant operations more stable and dependable.

Such technical improvements demonstrate how targeted filtration ensures the protection of critical components. Filtered water reduces wear, prolongs maintenance intervals, and contributes to the stable and reliable operation of the plants.

FAQ on Pumped Storage Power Plants and Filtration Technology

Pumped storage power plants are regarded as highly reliable because they can supply electricity very quickly when there is a shortage in the grid. Water is released from the upper reservoir directly to the turbines, allowing power generation to start immediately. They operate independently of wind or sunlight and therefore compensate for fluctuations from other energy sources. In addition, surplus electricity can be used to pump water back into the upper reservoir, ensuring the plants remain ready for operation at all times.

Water quality is critical because dirt particles or rust can damage sensitive hydraulic components and impair their function. Contamination leads to increased wear, leakage, or malfunctions in control operations. Reliable filtration therefore ensures that components operate precisely and safely over the long term.

The selection of a suitable filtration system is primarily influenced by water quality and the expected particle load. Equally important are the requirements of the components being protected, such as the sensitivity of sealing surfaces or the required filtration fineness. Material resistance, service life, and maintenance effort are also key factors, as these plants are often operated for decades. In addition, a filtration system should be easy to integrate into existing infrastructure without extensive modifications.

Optimized filtration processes reliably keep dirt, rust, and other particles away from sensitive components, thereby reducing wear. When components remain clean, they operate reliably for longer periods and require less frequent inspection or replacement. This significantly extends maintenance intervals and increases plant availability. For tailored filtration solutions, you can contact DANGO & DIENENTHAL Filtration at any time.